description

back-up rings have no intended sealing function. instead, as their name indicates, they are protective and supporting elements made from extrusion-resistant materials which generally have a rectangular cross section. they are installed in a groove together with an elastomeric sealing element preferably with a corresponding o-ring in static appli- cations.

due to the tight fit of the back-up ring in the housing, they prevent extrusion of the pressurised elastomeric sealing element into the sealing gap common inactive back- up ring, mainly used with o-ring to avoid gap extrusion. split and non split design avail- able.

slit bearing component with rectangular cross-section for ISC o-ring sealing on the out- side & inside.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

applications

bearing element to prevent gap extrusion of radial sealing ISC o-ring used dynamically.

- injection moulding machines.

- machine tools.

- presses.

- excavators.

- agricultural machines.

- valves for hydraulic circuits.

advantages

- use of o-ring in high pressure applications.

- use of o-ring materials with a low hardness.

- compensation of radial sealing gaps.

- use for internal and external sealing applications.

- reciprocating and rotating movements possible.

- compensation for large temperature fluctuations.

- static and dynamic applications.

- enlargement of the operating conditions of o-ring.

- high material and product quality.

- wide selection of standard dimensions.

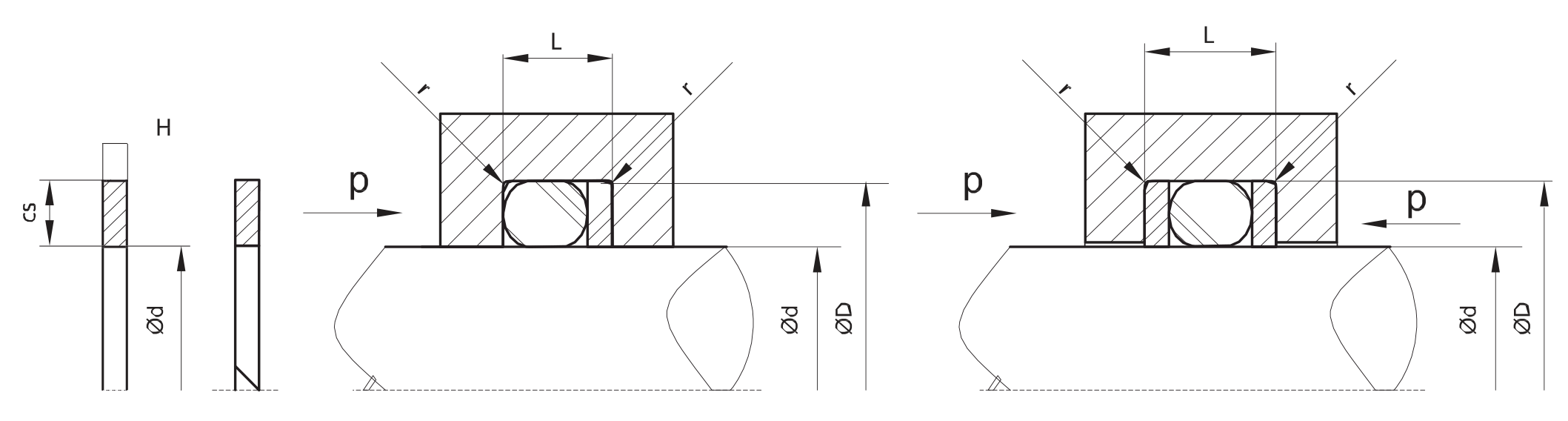

external sealing (bore)

back-up ring types, uncut

- rectangular cross sec

- static and dynamic use.

- reciprocating and rotating movements possible.

back-up ring types, cut

- rectangular cross sec

- cut angle of 30° or 45°.

- static and dynamic use.

- reciprocating and rotating movements possible.

- preferred for installations in a closed groove where uncut back-up rings are not suitable.

internal sealing (rod)

back-up ring types, uncut

- rectangular cross sec

- static and dynamic use.

- reciprocating and rotating movements possible.

back-up ring types, cut

- rectangular cross sec

- cut angle of 30° or 45°.

- static and dynamic use.

- reciprocating and rotating movement possible.

- preferred for installations in closed grooves where uncut back-up rings are not suitable.

operating parameters & material

| material | temperature |

| POM | -50 °C … +100 °C |

| PA | -40 °C … +100 °C |

| PTFE virgin | -200 °C … +260 °C |

| PTFE glass | -200 °C … +260 °C |

| PTFE bronze | -200 °C … +260 °C |

| PTFE carbon | -200 °C … +260 °C |

| PU | -30 °C … +110 °C |

| HPU | -20 °C … +110 °C |

| LTPU | -50 °C … +110 °C |

| GPU | -30 °C … +110 °C |

| NBR | -30 °C … +100 °C |

| FKM | -20 °C … +200 °C |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

2 POM up to ø260 mm, PA above ø260 mm

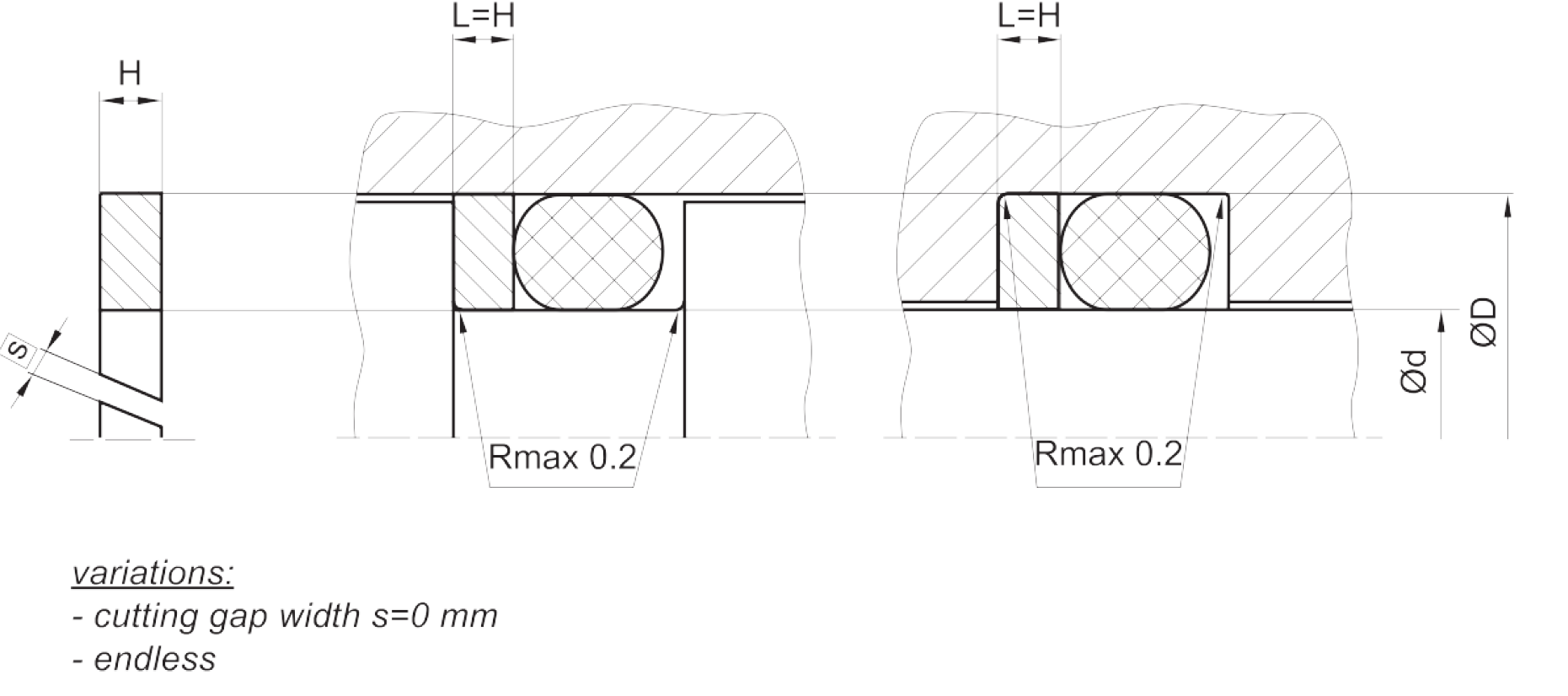

tolerance recommendation

surface finish according to o-ring instructions

| seal housing | tolerances |

| Ød | h7 |

| ØD | H9 |

the location of the sealing surface is determinant for the functionality

| seal housing | tolerances |

| Ød | h9 |

| ØD | H8 |

design instructions

the recommendations for o-ring (see catalogue “o-ring“) are generally valid for the use of back-up rings. this applies to the groove design, sur- face roughness, lead-in chamfers, etc.

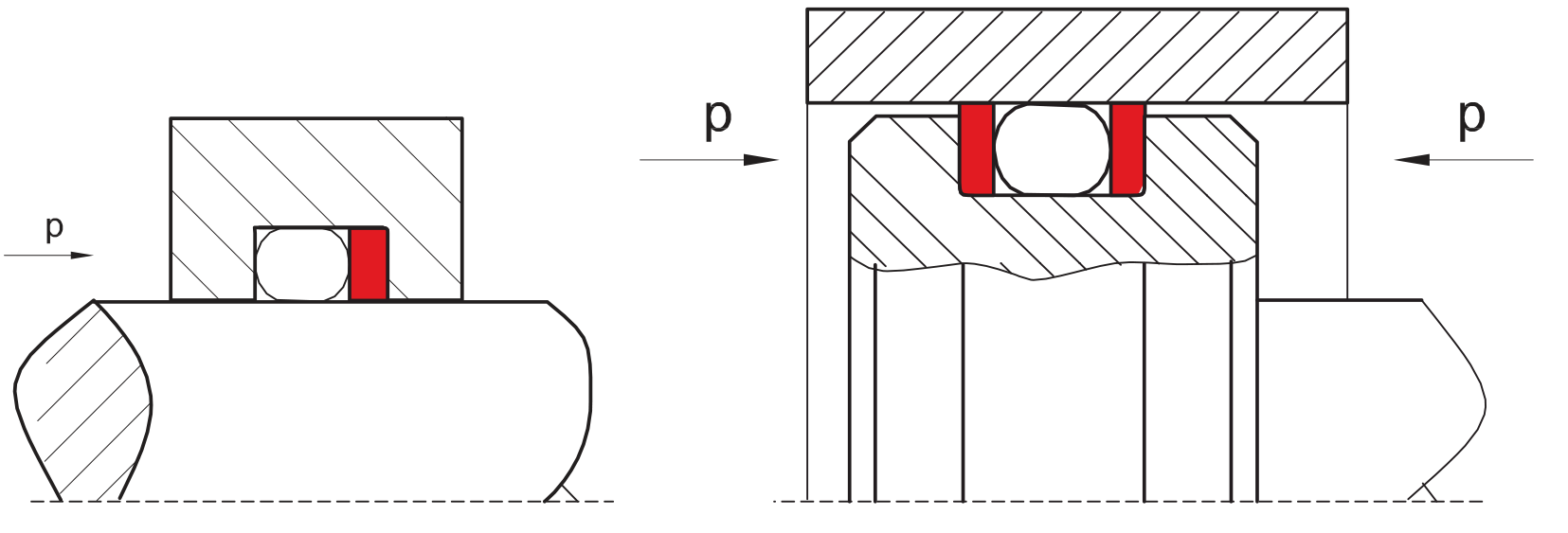

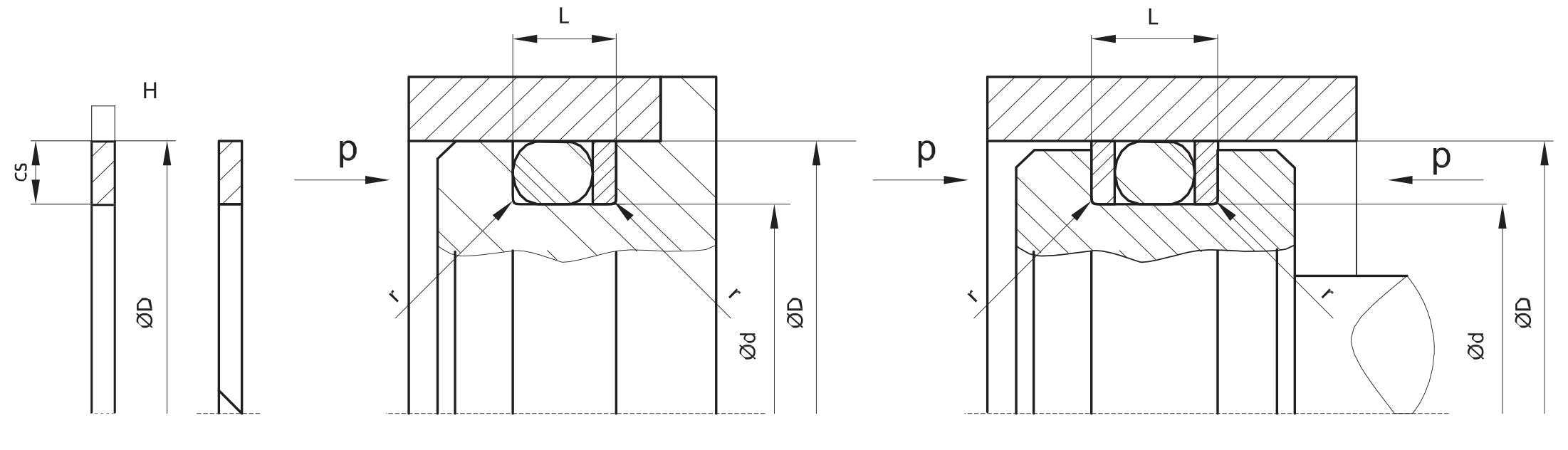

when the pressure is applied from one side only, it is sufficient to install a back-up ring on the downstream side of the o-ring. when the seal is exposed to pressure from both sides, two back-up rings -one on each side of the o-ring have to be used.

permissible sealing gap

the use of back-up rings allows the service pressure and/or permissible sealing gap specified in our o-ring catalogue to be increased. back-up ring installation, depending on the direction of the pressure.(see figure below).

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

installation recommendations static & dynamic application

external sealing (bore), back-up ring types, uncut & cut, r max 0,2mm