description

O-Ring activated symmetric piston seal for simple standard applications, not recommended for new designs.

- symmetric single acting piston compact seal. an O-ring inserted into the groove increases the preload.

- no interference fit on the inside diameter.

- various materials are available for different purposes.

- snaps into simple grooves (see notes on installation).

- best sealing effect across a wide temperature range.

- sealing effect enhanced by high recovery rate.

- for pressures up to 400 bar as a seal between pressurised spaces.

- good sealing in low pressure ranges.

- excellent static and dynamic sealing.

- suitable for short travel.

- no reverse leakage (i.e. minor relative motion of the sealing edges when thedirection is changed).

- recommended when holding or positioning under pressure.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

single acting

the PS 07 eal is designed for use as a piston seal – either single or double acting where two seals are used ‘back to back’

area of application: hydraulics

- reciprocating pistons in hydraulic cylinders.

- as piston seals for switching functions (e.g. clutch operation).

- as piston seals for clamping functions.

- replacement for rubber fabric seals of older equipment.

note

- under certain operating conditions, this seal may “pump” via the trailing side, e. as it does not fit tightly on the inside diameter, small amounts of operating media may be pressed out when the seal is deformed under pressure which may result in additional drag pres- sure built up.

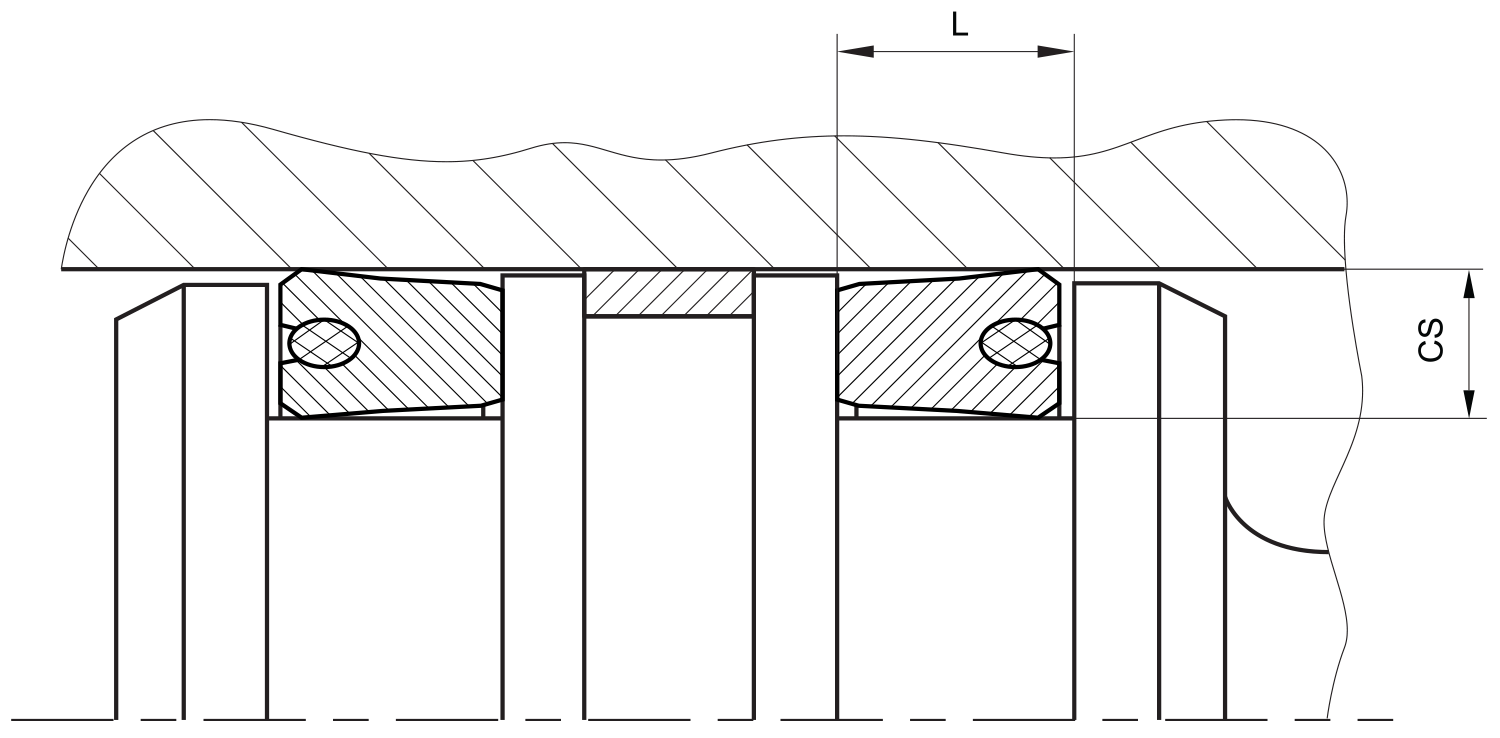

- the ratio between nominal width and sealing height cs/H should not drop below a value of 1/1.25 (essentially according to ISO 5597 housings for piston and rod seals).

- high degree of fric

- high break-away moment.

- the recovery volume is smaller than with simple lip seals.

- cross-section limited to 20

- not suitable for new designs (prefer the more modern K03-P type).

function

PS 07 profiles are compact seals designed to seal pressurised space against the atmosphere or – in case of back to back arrangement with intermediate guidering – to seal between two pressurised spaces, mainly for reciprocating movements. the design is based on applica- tion in standard hydraulic systems with conventional hydraulic oils. the operating parameters are as defined in the sealing data sheet and material data. requirements deviating from these parameters can be met to a certain degree by changing the geometry in the software program.

operating parameters & material

| sealing element | back-up ring | temperature | max. surface speed | max. pressure 1 | hydrolysis | dry running | wear resistance |

| PU | NBR | -30 °C … +100 °C | 0,5 m/s | 400 bar (40 MPa) | – | + | ++ |

| HPU | NBR | -20 °C … +100 °C | 0,5 m/s | 400 bar (40 MPa) | – | + | ++ |

| SPU | NBR | -30 °C … +100 °C | 0,5 m/s | 400 bar (40 MPa) | – | + | ++ |

| LTPU | NBR | -20 °C … +100 °C | 0,7 m/s | 400 bar (40 MPa) | – | ++ | ++ |

| GPU | NBR | -30 °C … +100 °C | 0,5 m/s | 400 bar (40 MPa) | – | + | ++ |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

++ … particularly suitable o … conditional suitable

+ … suitable – … not suitable

for detailed information regarding chemical resistance please refer to our „list of resistance“. for increased chemical and thermal resistance rubber

materials are to be preferred, attention should be paid to restrictions for pressure range and wear resistance. for higher gliding speeds another system should be used (e.g. PTFE materials).

note on special materials:

other materials such as Viton, Silicone, EPDM, H-NBR, etc., can be used for the preload element, but they are only useful in specific cases (tem-

perature or chemical influences).

gap dimension

| operating pressure | cs = (ØD – Ød)/2 mm | |||||

| 4 | 5 | 7.5 | 10 | 12.5 | 15 | |

| safe extrusion gap (mm) | ||||||

| 200 bar (20 MPa) | 0.62 | 0.75 | 0.90 | 1.15 | 1.35 | 1.50 |

| 400 bar (40 MPa) | 0.27 | 0.36 | 0.45 | 0.55 | 0.65 | 0.75 |

| 600 bar (60 MPa) | 0.17 | 0.19 | 0.21 | 0.23 | 0.25 | 0.26 |

| 700 bar (70 MPa) | 0.05 | 0.07 | 0.10 | 0.13 | 0.15 | 0.17 |

important note:

the above data are maximum value and can’t be used at the same time. e.g. the maximum operating speed depend on material type, pressure, tem- perature and gap value. temperature range also dependent on medium.

the table applies to an operating temperature of 70 °C.

use larger cross sections to increase maximum allowed gap dimension. if the permissible extrusion gap cannot be achieved, K04-P is to be used.

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,1-0,5 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,1-0,5 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

mode of installation

for inside diameters of 40mm and more, the seal can generally be slipped over the piston and snapped into closed grooves. due to occuring de- formation force at installation, assembly aid tools are to be used for large cross-sections. the material deformation should not exceed the value of 20%, otherwise the permanent deformation would be too large.

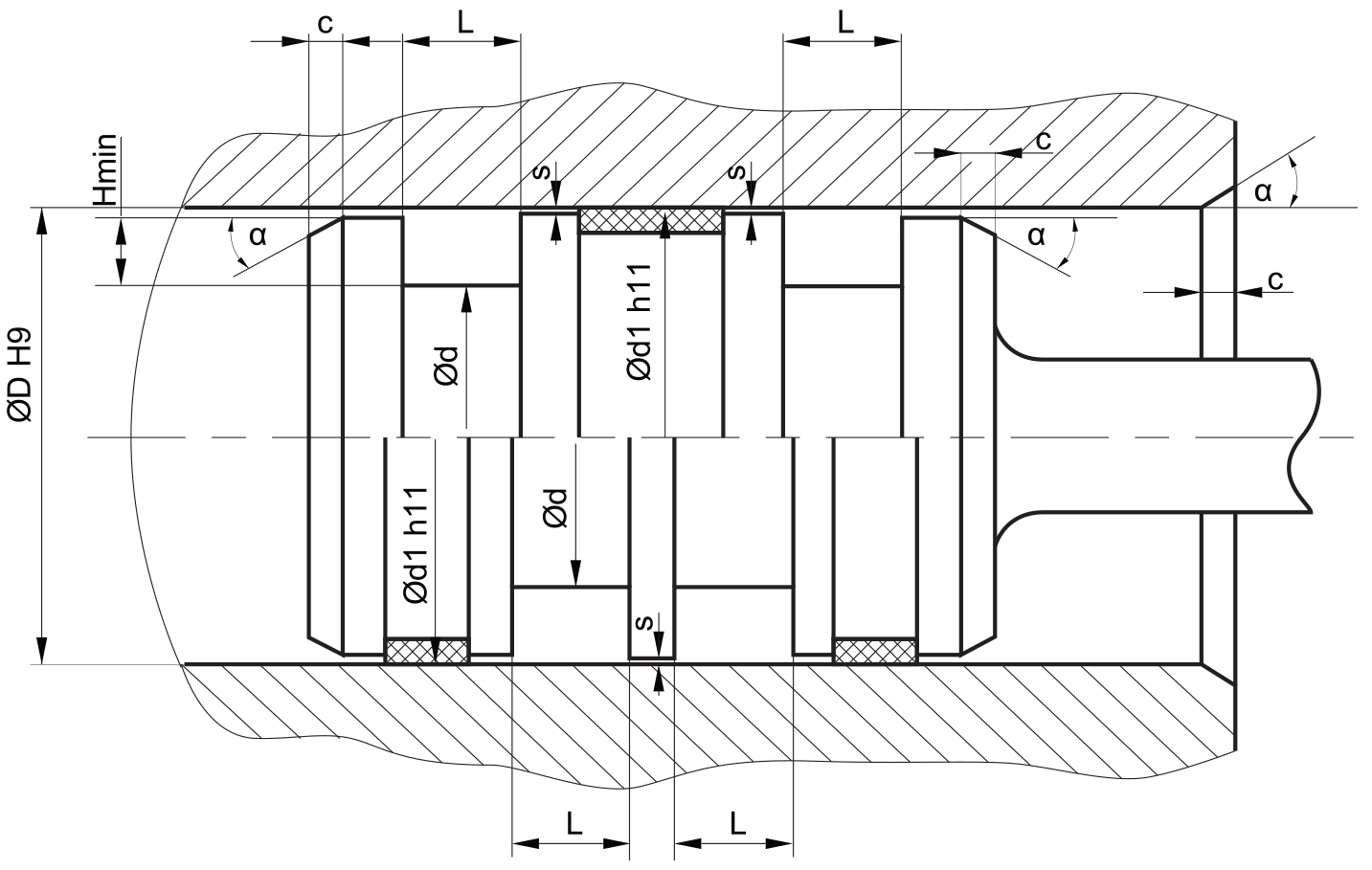

recommended mounting space:

plastic guiderings (wearbands) have to feature a adequate cutting gap (recommendation: 2-5% of D). if metalic guides are used, spiral grooves shall be provided. smaller values for Hmin will ease the installation (reduced elongation and mounting force) but the height of the retaining col- lar has to be sufficient to assure a stable fit in the housing ( larger than cs/2, smaller retaining collars will increase the danger of eversion of the profile in case of occuring drag pressure).

in order to avoid drag pressure built up in case of back-to-back arrangement, the distance between the seals should be as small as possible.

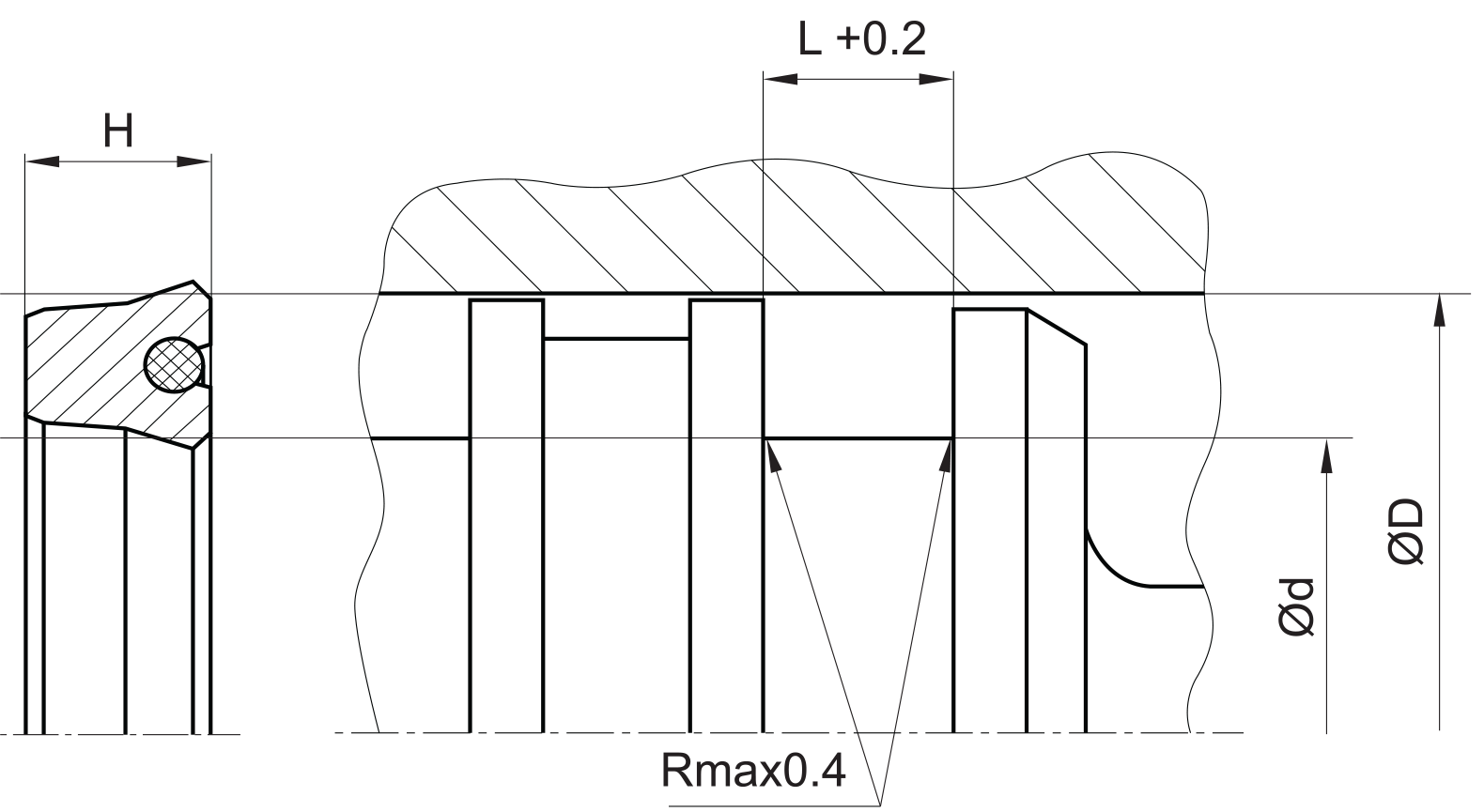

insertion chamfer:

in order to avoid damage to the piston seal during installation, the piston and the housing is to be chamfered and rounded as shown in the “recommended mounting space” drawing. the size of chamfer depends on the seal type and profile width.

| cs (mm) | c (mm) | |

| α = 15⁰ … 20⁰ | α = 20⁰ … 30⁰ | |

| 4 | 3.5 | 2 |

| 5 | 4 | 2.5 |

| 6 | 4.5 | 3 |

| 7.5 | 5 | 4 |

| 10 | 6 | 5 |

| 12.5 | 8.5 | 6.5 |

| 15 | 10 | 7.5 |

| 20 | 13 | 10 |

instead of a chamfer, the piston can also be designed with a radius. recommended size of the radius is equal to size of chamfer (R=c).

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

the ratio between nominal width and seal height cs/H should not drop below 1/1.25. therefore we recommend the following housing heights.

| ØD [mm] | Ød [mm] | L [mm] | cs = (ØD – Ød)/2 [mm] |

| 5 ~ 24,9 | ØD – 8 | 6 | 4 |

| 25 ~ 49,9 | ØD – 10 | 7 | 5 |

| 50 ~ 74,9 | ØD – 12 | 8 | 6 |

| 75 ~ 149,9 | ØD – 16 | 10 | 7.5 |

| 150 ~ 299,9 | ØD – 20 | 12 | 10 |

| 300 ~ 500 | ØD – 24 | 18 | 12.5 |

| 500 ~ 750 | ØD – 30 | 20 | 15 |

| > 750 | ØD – 40 | 26 | 20 |

fitted:

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.