description

the PS08-AQ5 is a double-acting seal consisting of a seal ring of high-grade modified PTFE

filled material, a X-Ring seal and an O-Ring as energizing element.

the K61 seal ring and the X-Ring seal together assume the dynamic sealing function whilst the O-Ring performs the static sealing function.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

double acting

the PS08-AQ5 seal is designed for use as a piston seal.

area of application: hydraulics

the PS08-AQ5 is the recommended sealing element for double acting pistons of accumulators and positioning and holding cylinders for:

- machine tools

- presses

- accumulators

- stabilisers

- heavy duty suspension cylinders

media: for all common hydraulic fluids, including bio-oils and gases.

design

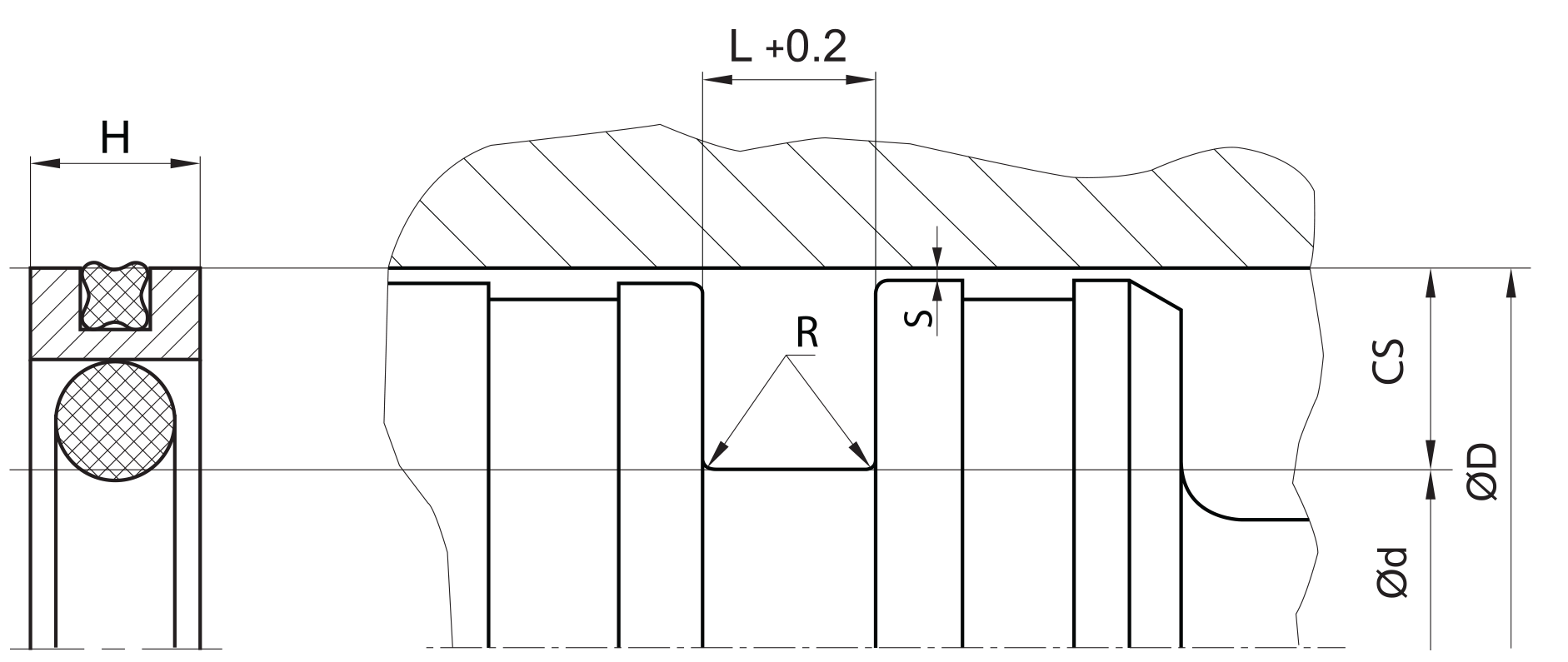

the PS08-AQ5 is supplied as standard with radial notches on both sides. these ensure direct pressurizing of the seal under all operating condi- tions.

advantages

- high sealing effect in applications requiring media separation, e.g. fluid/fluid or fluid/gas

- double security through the combination of low-friction special materials with elastomer seals

- outstanding sliding properties, no stick-slip effect

operating parameters & material for standard application:

for hydraulic components in mineral oils or medium with good lubricating performance.

standard material for hydraulics, high compressive strength, good sliding and wear properties, good extrusion resistance, BAM tested. mating surface material: steel tubes, steel hardened cast iron.

colour: greyish to dark brown.

operating parameters & material for special application:

for special applications requiring other material combinations, please contact our technical department for further information.

for all lubricating and non-lubricating hydraulic fluids, hydraulic oils without zinc, water hydraulic, soft mating surfaces. Surface texture not suit- able for gases.

mating surface material: steel, cast iron, stainless steel, aluminium, bronze, alloys colour: grey

operating parameters & material for standar application:

for hydraulic components in mineral oils or medium with good lubricating performance.

for oil hydraulic and pneumatic for all lubricating and non-lubricating fluids, high extrusion resistance, good chemical resistance, BAM tested mating surface material: steel, stainless steel

colour: black

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

2 attention: not suitable for mineral oils!

gap dimension

important note:

the above data are maximum value and can’t be used at the same time. e.g. the maximum operating speed depend on material type, pressure, tem- perature and gap value. temperature range also dependent on medium.

surface quality

| surface roughness | material |

Rtmax (μm) |

Rz DIN [µm] |

Ra (μm) |

| mating surface | PTFE + …… | 0.63 – 2.50 | 0.40 – 1.60 | 0.05 – 0.20 |

| PU & Rubber | 1.00 – 4.00 | 0.63 – 2.50 | 0.10 – 0.40 | |

| groove surface | < 16 | < 10.0 | < 1.6 | |

tolerance recommendation

| seal housing | tolerances |

| Ød | h9 |

| ØD | H9 |

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.