description

chevron sealing set, design with extremely flexible sealing lips for difficult operating conditions like bad guiding, large tolerance range. availableas total chevron sealing set as well as intermediate chevrons only (in case of metal male andfemale adapters).

- asymmetric single-acting piston sealing set consisting of several chevrons, com- bined with pressure and support ring to form a set. pressure and support ring are mainly made of metal or already integrated in metal housing.

- various materials are available for different purposes.

- good sealing in the higher pressure range.

- for pressures up to 500 bar as a seal between pressurised spaces.

- good static and very good dynamic sealing.

- suitable especially for very long travel.

- low friction due to flexible lip design.

- open mounting space are required (see mode of installation).

- by varying the number of packings,friction as well as leakage behavior can be influenced (at least 2 chevrons).

- mainly used for repair purposes.use more modern systems for new designs.

- the long,flexible lip can compensate guide clearance (e.g.: on long strokes).

- due to the low contact pressure on the sealing lip surface,the piston can move back easily.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined only.

single acting

the PS 32 seal is designed for use as a piston seal – either single or double acting where two seals are used ‘back to back’

area of application: hydraulics

- linearly acting rods on hydraulic cylinders; plunger in down- and upstroke presses.

- spindle seal at valves (at fittings).

- cylinders with very long strokes,e.g. lifting ramps or hydraulic elevators.

note

- expensive and complex design.

- former designs mainly made in fabric reinforced rubber.replacing such fabric reinforced rubber seals by polyurethane seals will

reduce the lubricating film (attention in case of more sealing rings).

- reworked housings (changed cross-section) require adapted pressure and support rings made of plastic. if this is not possible (if pres-

sure and support rings are integrated in the housing), it is recommended to consult our technical department for clarification.

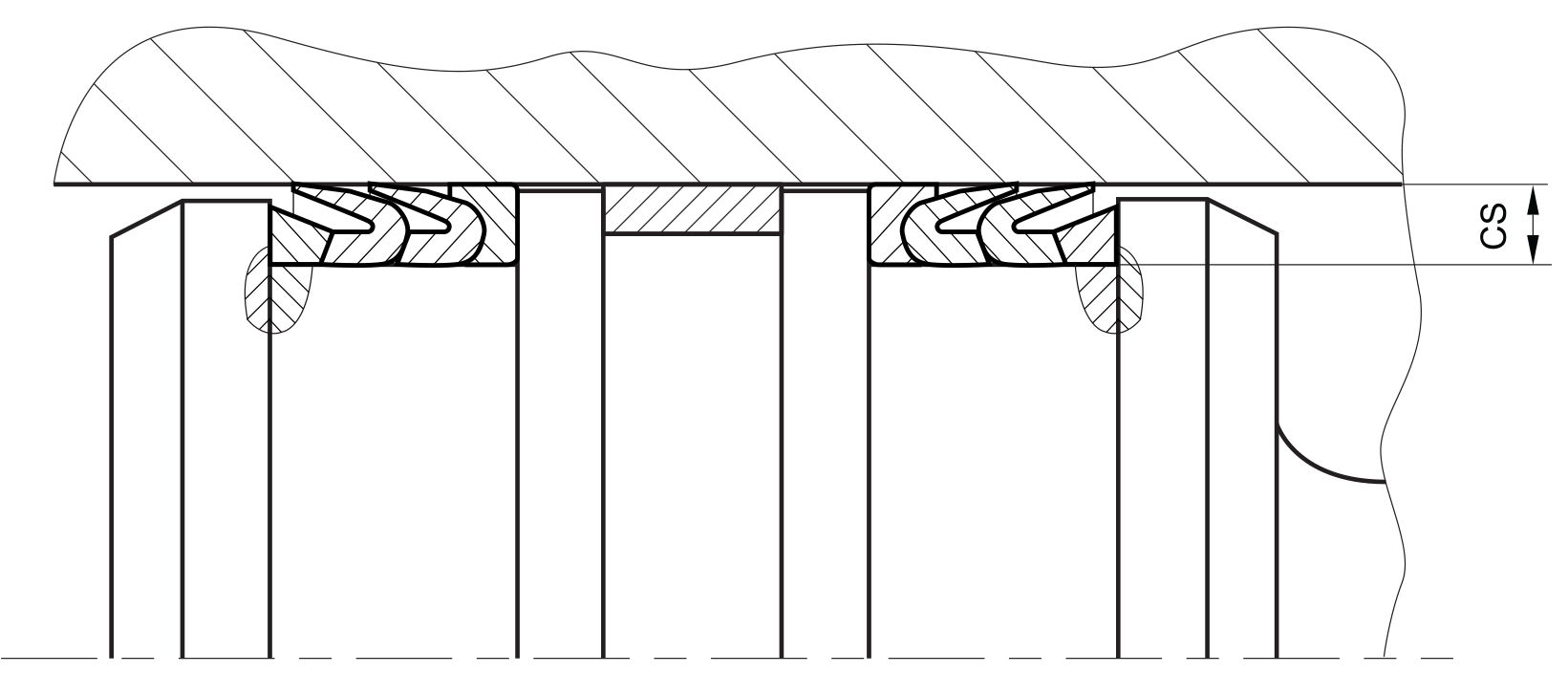

function

PS 32 profiles are single acting piston seal sets designed to seal pressurised space against the atmosphere or – in case of back to back ar- rangement with intermediate guide ring to seal between two pressurised spaces, mainly for reciprocating movements. the design is based on application in standard hydraulic systems with conventional hydraulic oils. the operating parameters are as defined in the sealing data sheet and material data. requirements deviating from these parameters can be met to a certain degree by changing the geometry in the software program.

operating parameters & material

| material | temperature | max. surface speed | max. pressure 1 | hydrolysis | dry running | wear resistance | |

| sealing element | back-up ring | ||||||

| PU | POM / PA | -30 °C … +100 °C | 0.5 m/s | 250 bar (25 MPa) | – | + | + |

| HPU | POM / PA | -20 °C … +100 °C | 0.5 m/s | 250 bar (25 MPa) | + | + | + |

| LTPU | POM /PA | -40 °C … +110 °C | 0.5 m/s | 250 bar (25 MPa) | – | + | + |

| SLPU | POM / PA | -20 °C … +100 °C | 0.7 m/s | 250 bar (25 MPa) | + | ++ | + |

| GPU | POM / PA | -30 °C … +100 °C | 0.5 m/s | 250 bar (25 MPa) | + | + | + |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

2 POM up to ø260 mm, PA above ø260 mm

++ … particularly suitable o … conditional suitable

+ … suitable – … not suitable

gap dimension

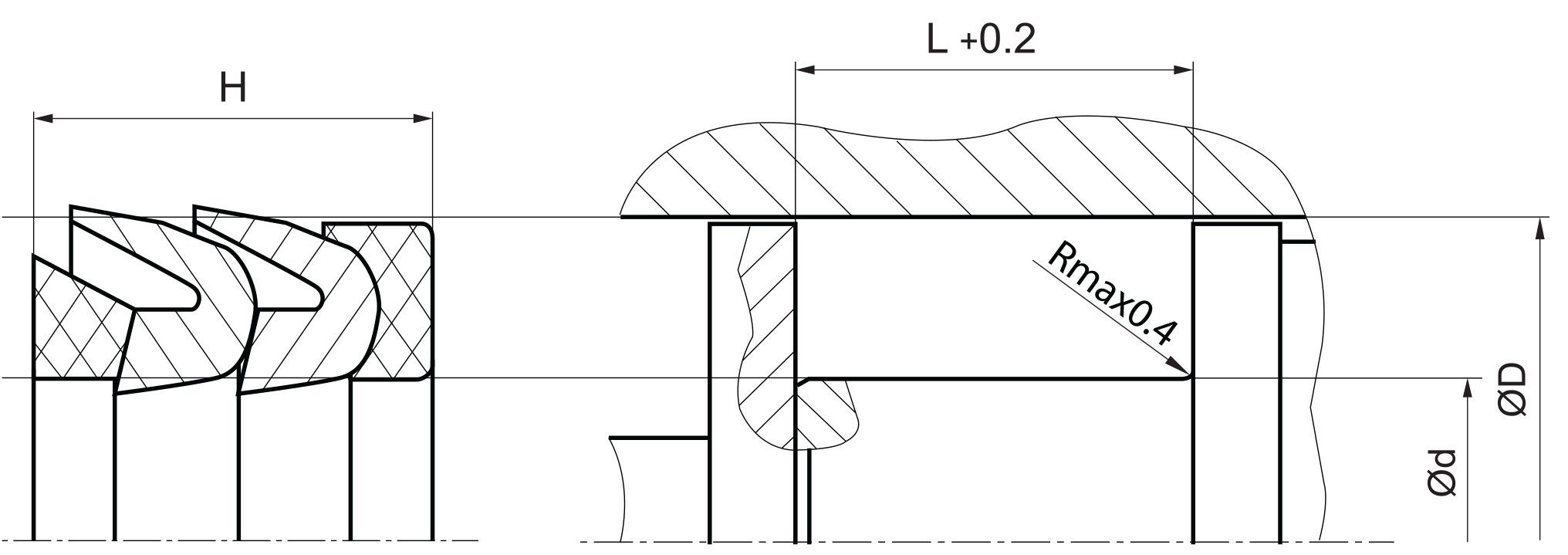

when using a pressure ring, the extrusion gap is already integrated in the seal. the gap between piston and housing should not exceed cs·0.05.

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,05-0,3 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| Ød | h9 |

| ØD | H9 |

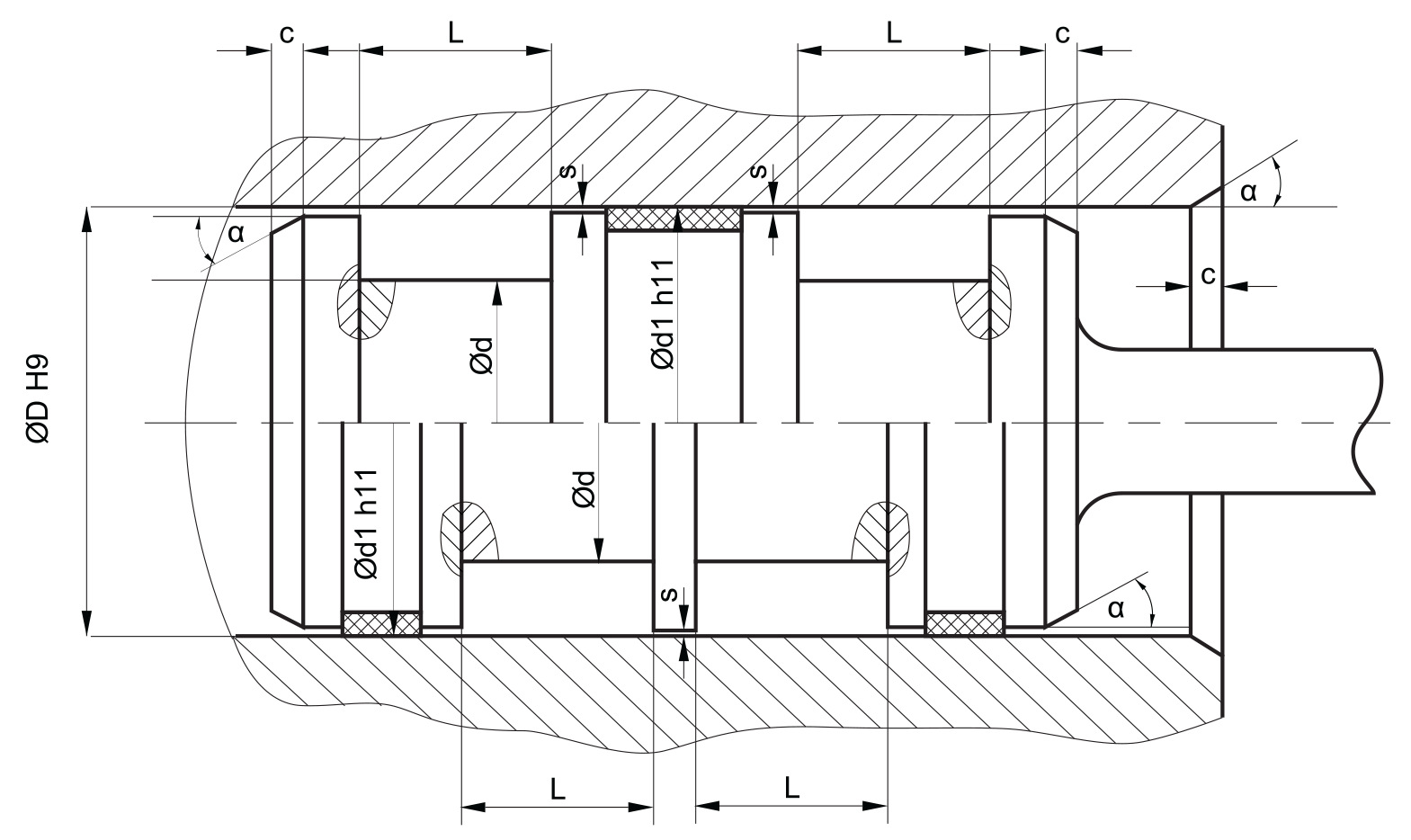

mode of installation

open housings are required.

recommended mounting space:

plastic guiderings (wearbands) have to feature a adequate cutting gap (recommendation: 2-5% of D). if metalic guides are used, spiral grooves shall be provided. in order to avoid drag pressure built up in case of back-to-back arrangement, the distance between the seals should be as small as possible.

insertion chamfer:

in order to avoid damage to the piston seal during installation, the piston and the housing is to be chamfered and rounded as shown in the “recommended mounting space” drawing. the size of chamfer depends on the seal type and profile width.

| cs (mm) | c (mm) | |

| α = 15⁰ … 20⁰ | α = 20⁰ … 30⁰ | |

| 4 | 3.5 | 2 |

| 5 | 4 | 2.5 |

| 6 | 4.5 | 3 |

| 7.5 | 5 | 4 |

| 10 | 6 | 5 |

| 12.5 | 8.5 | 6.5 |

| 15 | 10 | 7.5 |

| 20 | 13 | 10 |

instead of a chamfer, the piston can also be designed with a radius. recommended size of the radius is equal to size of chamfer (R=c).

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

this profile is only a replacement in already existing housings. use new sealing systems in new designs

the nominal width and seal diameter should be in accordance with following recommendations:

| ØD [mm] | Ød [mm] | L [mm] | cs = (ØD – Ød)/2 [mm] |

| 5 ~ 24,9 | ØD – 8 | 6 | 4 |

| 25 ~ 49,9 | ØD – 10 | 7 | 5 |

| 50 ~ 74,9 | ØD – 12 | 8 | 6 |

| 75 ~ 149,9 | ØD – 16 | 10 | 7.5 |

| 150 ~ 299,9 | ØD – 20 | 12 | 10 |

| 300 ~ 500 | ØD – 24 | 18 | 12.5 |

| 500 ~ 750 | ØD – 30 | 20 | 15 |

| > 750 | ØD – 40 | 26 | 20 |

fitted:

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.