description

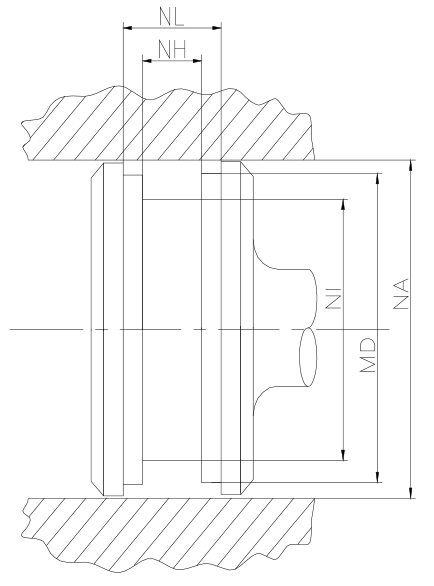

the PS 55 is a double-acting seal and guide element comprising an elastomeric profile seal ring, two back-up rings and two guide rings. the profile seal ring seals in both the static and dynamic range whilst the back-up rings prevent extrusion into the sealing gap. the function of the guide rings is to guide the piston in the cylinder tube and to absorb transverse forces. the design provides a compact seal and guide combination for a closed or split installation groove.

this type is characterized by the straight, long-sided l-profiles of the guide rings. compared with type K09-SB, it exhibits a smaller groove depth with the same cylinder diameter.

application

not bolded symbols; please consult our technical for application limitations

category of profile

molded/standard/trade product or machined with minor design change.

double acting

the PS 55 seal is designed for use as a piston seal.

area of application: hydraulics

the PS 55 are the recommended sealing element for double acting pistons of hydraulic components such as:

- machine tools

- truck cranes

- forklifts & handling machinery

- agriculture equipment

advantages

- good sealing effect, also suitable for holding cylinders.

- capable of installation in closed grooves for reduced machining costs.

- economic sealing and guiding solution.

- simple snap installation.

operating parameters & material

| material | temperature | max. surface speed | max. pressure 1 | ||

| sealing element | back-up ring | guide ring | |||

| NBR (70 Shore A) | polyester elastomer | POM | -30 °C … +100 °C | 0.5 m/s | 400 bar (40 MPa) |

| FPM | PTFE – Glass | PTFE + 40% BR | -30 °C … +200 °C | 0.5 m/s | 400 bar (40 MPa |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

2 POM up to ø260 mm, PA above ø260 mm.

media: mineral oil-based hydraulic fluids, flame retardant hydraulic fluids, HFA, HFB, HFC (< +40°C).

surface quality

| surface roughness | material | Rtmax [µm] | Rz DIN [µm] | Ra [µm] |

| mating surface | PTFE + …… | 0.63 – 2.50 | 0.40 – 1.60 | 0.05 – 0.20 |

| PU & Rubber | 1.00 – 4.00 | 0.63 – 2.50 | 0.10 – 0.40 | |

| groove surface | < 16 | < 10.0 | < 1.6 | |

gap dimension

the largest gap dimension occurring on the non-pressurised side of the seal in operation is of vital importance for the function of the seal.

tolerance recommendation

| seal housing | tolerances |

| Ød | h9 |

| Ød1 | h9 |

| ØD | H9 |

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.