description

profile ring-activated symmetric PTFE piston seal, similar to K09-D, but special heavy duty design for heavy industry hydraulics or for special housing dimen- sions. PS 81 can be used where a piston has pressure on both sides and is designed especially for large diameters.

very high resistance to pressure, design prevents twisting, very good protection against extrusion, high resistance to abrasion, good thermal conductivity, low friction, free of stick-slip, high contact pressure due to elastomer profile ring.

- asymmetric double-acting composite piston seal, with a gliding part made of low-friction material and an elastic preload element.

- interference fit on the inside diameter.

- various materials are available for different purposes.

- snaps into simple grooves (see notes on installation).

- the generously dimensioned chamfer reduces the risk of gap extrusion.

- the massive profile ring makes only small relative movements and is thus not subject to specific wear.

- preferably used for heavy-dutyapplications.

- for standard application only if an O-ringis not available.

- good sealing effect across wide temperature ranges.

- for pressures up to 400 bar (in special cases up to 800 bar) as a seal between pressurized spaces.

- good static and dynamic sealing.

- suitable for short and long travel with extremely slow or quick movements.

- no stick slip.

- small break-awayload after prolonged periods of standstill.

- exact positioning due to little friction.

- high mechanical efficiency.

- insensitive to thermal damage caused by air in the oil.

- no drag pressure build-up.

- high distortion stability.

- high pressing force due to rubber profile ring.

- radial grooves assure a fast pressure activation of the seal (design and arrangement see “fabrication tolerances for machined seals” ES222.308-D).

- this seal can run over holes which are smaller than nominal seal height if the holes have suitable chamfered edges.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

double acting

the PS 81 seal is designed for use as a piston seal.

area of application: hydraulics

- reciprocating pistons on hydraulic cylinders,small swiveling motion permissible.

- especially for larger diameter and heavy-dutyhydraulic applications.

- as piston seal for small permissible frictional forces or if smooth running is required.

- for heavy-dutyoperating conditions.

note

- the ratio between nominal width and sealing height NB/H should range between 1/0.75 and 1/1.5.

- because of the fluid transport between the pressurised spaces this seal can only be used to seal same media.

function

PS 81 profiles are composite rod seals designed to seal between pressurized spaces; mainly for reciprocating movements. the design is based on application in standard hydraulic systems with conventional hydraulic oils.

the operating parameters are as defined in the sealing data sheet and material data. requirements deviating from these parameters can be met to a certain degree by changing the geometry in the software program.

operating parameters & material

| material | temperature | max. surface speed | max. pressure 1 | hydrolysis | dry running | wear resistance | |

| sealing element | energizer | ||||||

| s-mart PTFE glass | s-mart NBR | -30 °C … +100 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE bronze | s-mart NBR | -30 °C … +100 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE carbon | s-mart NBR | -30 °C … +100 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE glass | s-mart FKM | -20 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE bronze | s-mart FKM | -20 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE carbon | s-mart FKM | -20 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | – | ++ | + |

| s-mart PTFE glass | s-mart EPDM2 | -50 °C … +150 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart PTFE bronze | s-mart EPDM2 | -50 °C … +150 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart PTFE carbon | s-mart EPDM2 | -50 °C … +150 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart PTFE glass | s-mart MVQ | -60 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart PTFE bronze | s-mart MVQ | -60 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart PTFE carbon | s-mart MVQ | -60 °C … +200 °C | 10 m/s | 400 bar (40 MPa) | ++ | ++ | + |

| s-mart UHMWPE | s-mart MVQ | -60 °C … +80 °C | 10 m/s | 400 bar (40 MPa) | ++ | + | + |

| s-mart XPU | s-mart NBR | -30 °C … +110 °C | 5 m/s | 600 bar (40 MPa) | |||

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

2 attention: not suitable for mineral oils!

++ … particularly suitable o … conditional suitable

+ … suitable – … not suitable

for detailed information regarding chemical resistance please refer to our “list of resistance”. for decreased leackage rates elastomer materials (polyure-

thane or rubber) in other sealing systems are to be preferred.

gap dimension

| operating pressure | cs = (ØD – Ød)/2 mm | |||||

| 5 | 7.5 | 10 | 12.5 | 15 | 20 | |

| safe extrusion gap (mm) | ||||||

| 100 bar (10 MPa) | 0.38 | 0.43 | 0.50 | 0.56 | 0.65 | 0.83 |

| 200 bar (20 MPa) | 0.28 | 0.32 | 0.35 | 0.42 | 0.50 | 0.64 |

| 300 bar (30 MPa) | 0.22 | 0.25 | 0.30 | 0.34 | 0.42 | 0.56 |

| 400 bar (40 MPa) | 0.19 | 0.22 | 0.24 | 0.29 | 0.36 | 0.49 |

important note:

the above data are maximum value and can’t be used at the same time. e.g. the maximum operating speed depend on material type, pressure, tem- perature and gap value. temperature range also dependent on medium.

the table refers to a operating temperature of 80°C. temperatures below may increase the safe extrusion gap slightly, at temperatures above

80 °C, the gap dimensions has to be reduced or a stronger profile selected.

for extrusion gap sizes resulting from tolerance pair H8/f8 pressure ranges above 400 bar can be reached in special cases, influences due to

thermal expansion have to be considered. we recommend to contact our technical department.

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,05-0,3 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

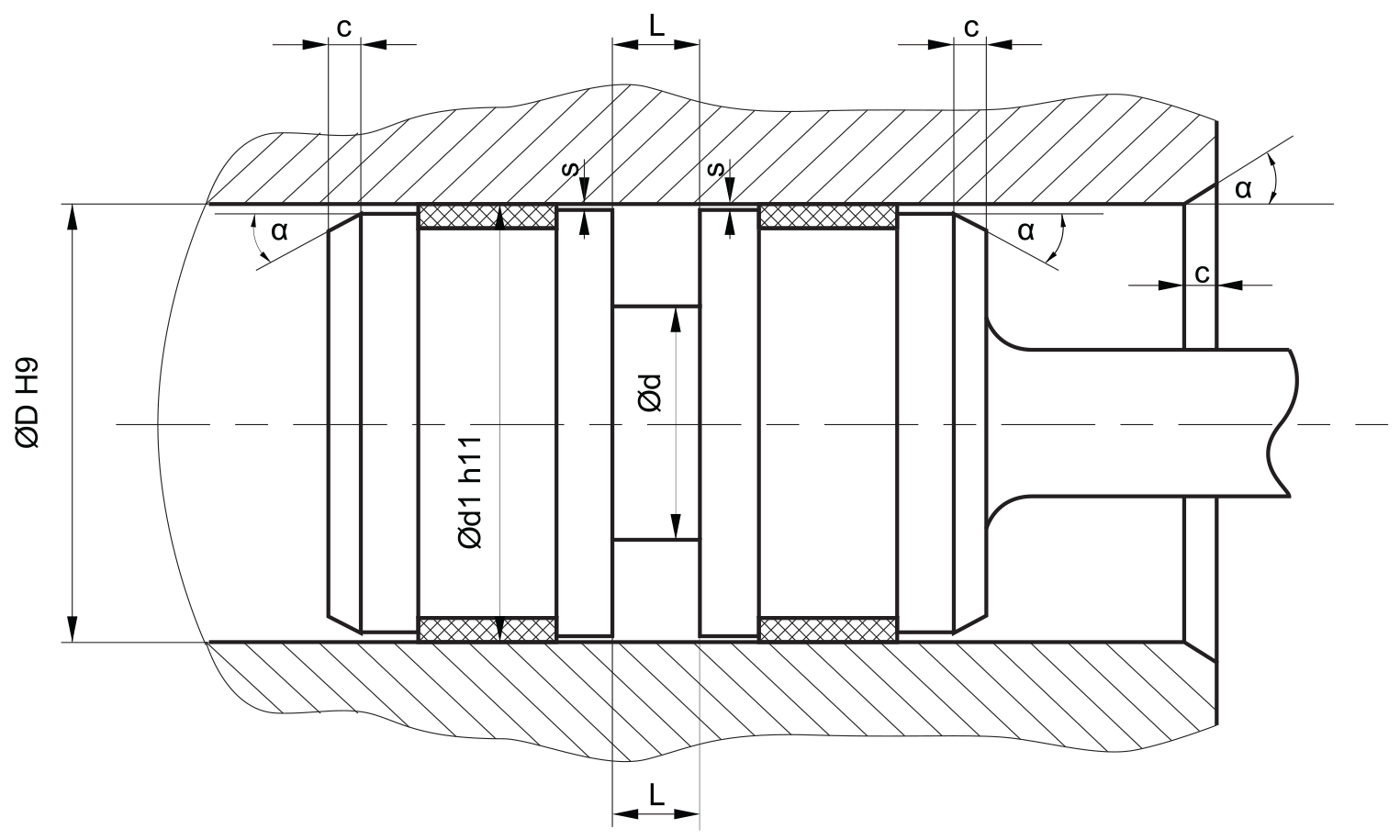

tolerance recommendation

| seal housing | tolerances |

| Ød | h10 |

| ØD | H9 |

mode of installation

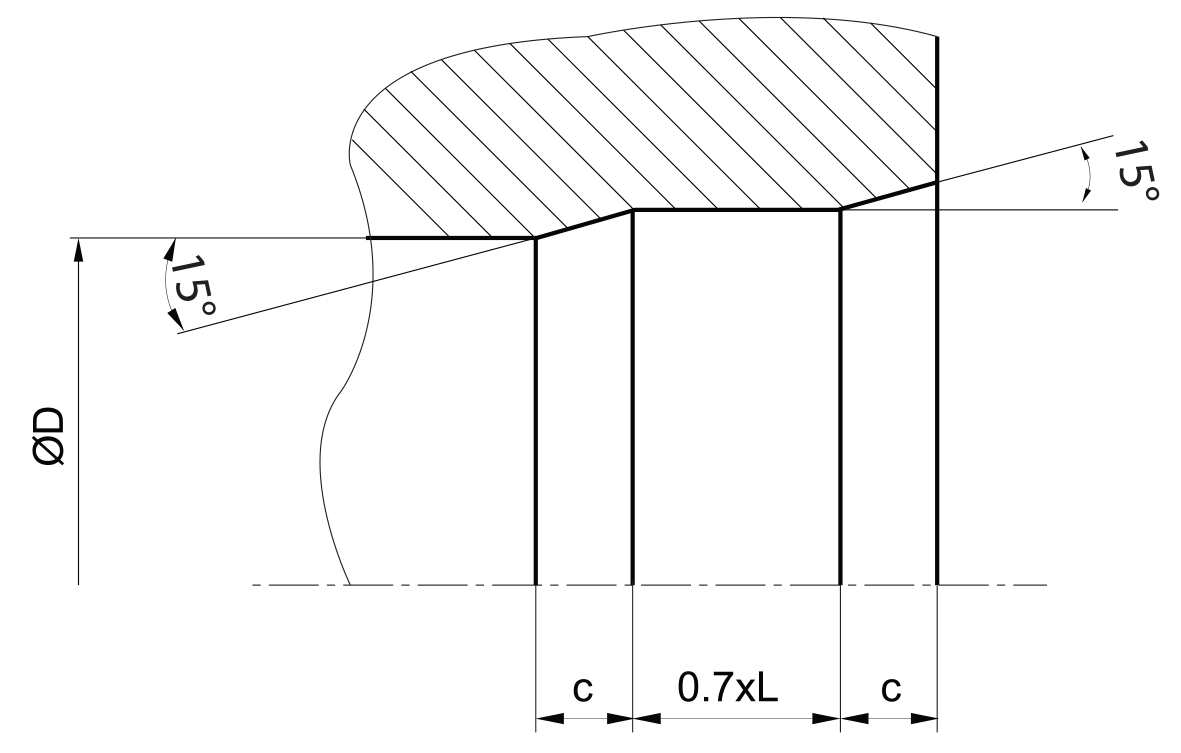

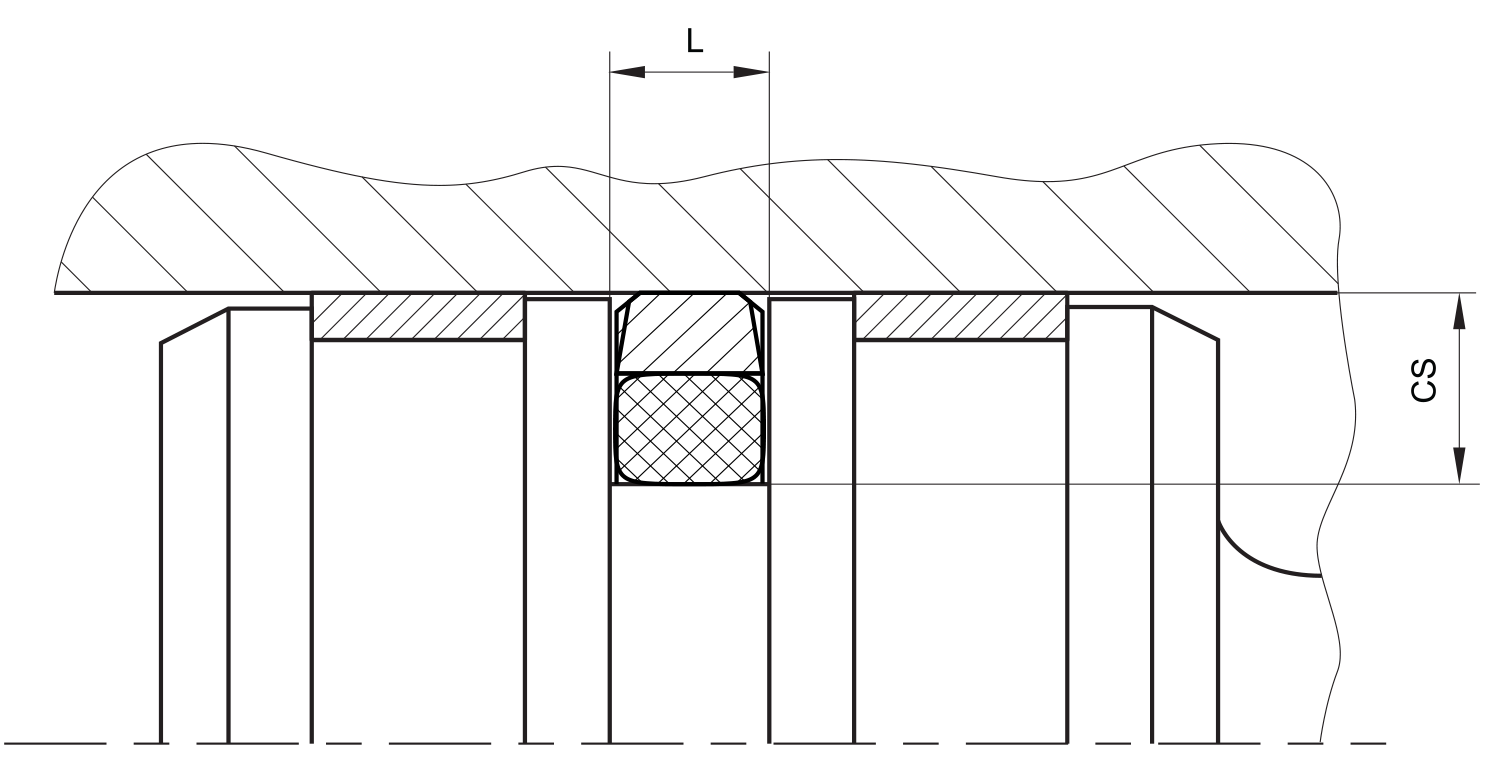

in case of closed grooves, it is not recommended to slip the seal over the piston by hand (uneven material deformation in the sealing part). after the O-Ring is placed into the groove, the sealing part should be stretched over a installation cone by using a sleeve (assembly aid tools).

a recovery of the sealing part with a calibrating sleeve is advisable, however, a special shaped insertion chamfer on the cylinder barrel can also be designed (danger of tilting). values for “c” see insertion chamfer.

recommended mounting space:

insertion chamfer:

in order to avoid damage to the piston seal during installation, the piston and the housing is to be chamfered and rounded as shown in the “recommended mounting space” drawing. the size of chamfer depends on the seal type and profile width.

| cs (mm) | c (mm) | |

| α = 15⁰ … 20⁰ | α = 20⁰ … 30⁰ | |

| 4 | 3.5 | 2 |

| 5 | 4 | 2.5 |

| 6 | 4.5 | 3 |

| 7.5 | 5 | 4 |

| 10 | 6 | 5 |

| 12.5 | 8.5 | 6.5 |

| 15 | 10 | 7.5 |

| 20 | 13 | 10 |

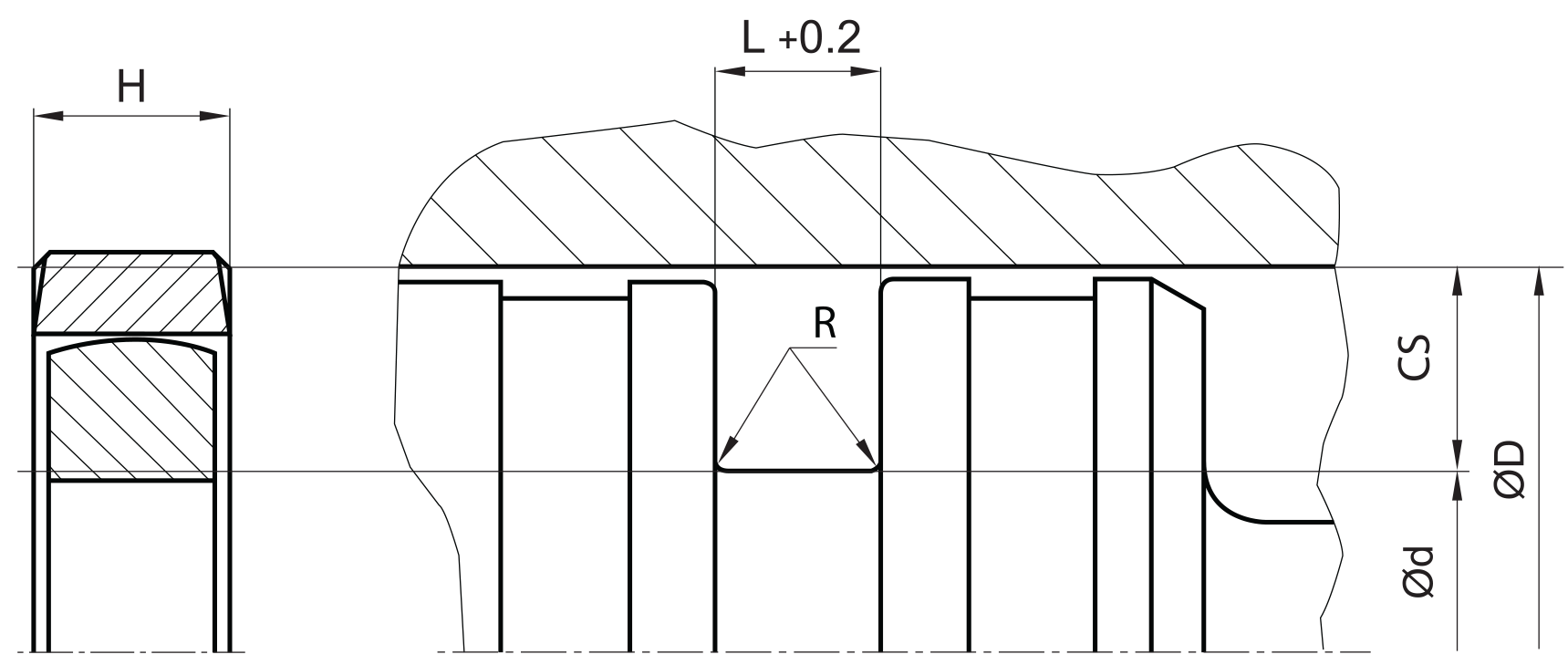

instead of a chamfer, the piston can also be designed with a radius. recommended size of the radius is equal to size of chamfer (R=c).

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

the ratio between nominal width and seal height should be in accordance to ISO 7425 part 1. we recommend the following values:

| ØD [mm] | ØD [mm] | L [mm] | cs = (ØD – Ød)/2 [mm] |

| 8 ~ 14,9 | ØD – 4,9 | 2,2 | 2.45 |

| 15 ~ 39,9 | ØD – 7,5 | 3.2 | 3.75 |

| 40 ~ 79,9 | ØD – 11 | 4.2 | 5.5 |

| 80 ~ 132,9 | ØD – 15,5 | 6.3 | 7.75 |

| 133 ~ 329,9 | ØD – 21 | 8.1 | 10.5 |

| 330 ~ 669,9 | ØD – 24,5 | 8.1 | 12.25 |

| 670 ~ 1000 | ØD – 28 | 9.5 | 14 |

| > 1000 | ØD – 28 | 9.5 | 14 |

| L | (ØD – Ød)/2 mm |

| ≤ 10 | max. 0,4 |

| > 10 …..≤ 1,5 | max. 0,8 |

| > 15 | max. 1,2 |

fitted:

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.