description

as profile R 10-A, but with a profile ring energizer instead of the O-ring. for heavy duty applications and non standard housings.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined only.

double acting rotary seal

area of application: hydraulics & pneumatics

the R 10-A is the preferably used as a double acting rotary seal for hydraulic and pneumatic equipment in sectors such as:

- rotary distributors

- high pressure valve stems

- manipulators

- pivoting motors in mobile hydraulic and machine tools

- hydraulic motors

excavators, grippers, rotary joints.

hydraulic rotary transmission leadthrough, sealing of swivelling and rotating shafts and rods

function

the R 10-A is a double acting seal which can be implemented with double-sided or reciprocal pressure admission. it is for internal seal- ing and is often used in a twin configuration. the seal face is particulary designed for use at high pressure and low speed. the peripheral grooves in the dynamic seal face provide for the formation of a lubricant depot. this results in decreased friction and good emergency running properties.

advantages

double-acting rod seal for pivoting motions in hydraulic systems, preferably for usage in hydraulic joints and rotary joints.

- short

- highly resistant to hydraulic fluids

- low friction, free of stick-slip

media

hydraulic oils, lubricating oils and other mineral oil based fluids, water, water and oil emulsion

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously.

surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤3 | ≤0,3 |

| bottom of groove | ≤10 | ≤1,8 |

| groove face | ≤16 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| Ød | h7 |

| ØD | H8 |

frictional power

guide values for the frictional power can be determined from the graph in figure below. they are shown as a function of the sliding speed and operating pressure for a shaft diameter of 50 mm with an oil temperature of 60° C. at higher temperatures, these application limits must be reduced.

guide values for other shaft diameters can be calculated using the formula:

the guide values apply for constant operating conditions. changes in operating conditions such as pressure fluctuations or alternating directions of shaft rotation can result in considerably higher friction values.

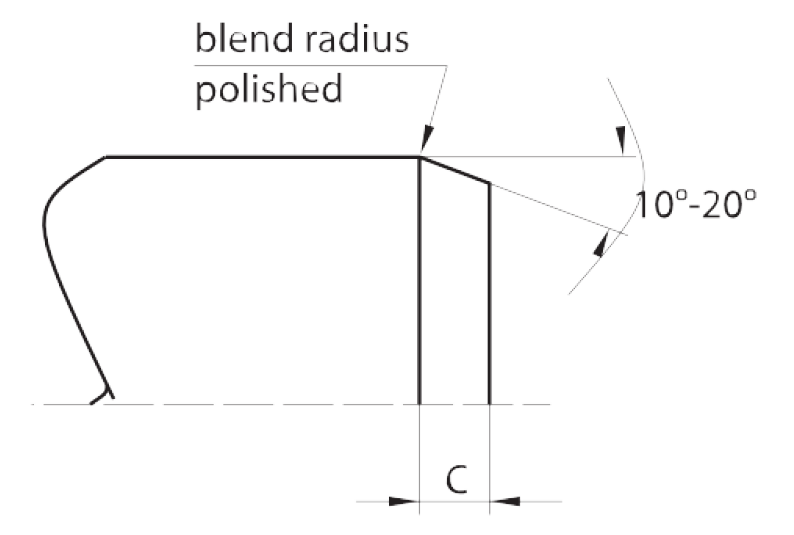

lead-in chamfers

in order to avoid damage during installation, lead-in chamfers and rounded edges must be provided on the rod (figures below). if this is not pos- sible for design reasons, a separate installation tool is recommended.

the minimum length of the lead-in chamfer depends on the profile size of the seal and can be seen from the following tables. if concentricity between the parts is not ensured during installation the lead-in chamfers must be increased correspondingly.

for the surface quality of the lead-in chamfer, the same recommendations apply as given for the sealing surfaces in standard housing dimen- sions.

installation

with small diameters, the seal requires split housing. with larger diameters, closed housing can be planned. subsequent calibration is recom- mended

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see seal-mart catalog…

the listing below is our suggestion for standard housing dimensions.

at pressures > 10 MPa it is recommendable that for the cross section you choose the next larger profile according to the column “available range“

i.e. for shaft Ø80 mm.

* at pressures > 30 MPa: use diameter tolerance H8/f8 (bore / rod) in area of seal.

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.