description

asymmetric rod seal for standard applications as RS01 but due to design with active back-up ring suitable for larger extrusion gaps or higher pressure range.

- asymmetric single-acting rod lip seals, with the dynamic sealing lip being shorter than the static one.

- interference fit on the outside diameter.

- various materials are available for different purposes.

- snaps into simple grooves (see notes on installation).

- best sealing effect across a wide temperature range.

- the active back up ring on the trailing side of the seal reduces extrusion wear and

- allows larger gap dimensions resp higher system pressure.

- sealing effect enhanced by high recovery rate.

- for pressures up to 700 bar as a seal between pressurized space and atmosphere.

- good sealing in the low pressure range.

- excellent static and dynamic sealing.

- suitable for long travel.

- little inclination to“stick-slip”.

- low break-awayload after prolonged periods of standstill.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined only.

single acting

the RS02-A seal is designed for use as a rod seal.

area of application: hydraulics

- reciprocating rods on hydraulic cylinders,push rods, fittings.

- rod seals for applications with large extrusion gap and without specific impact load.

note

- this seal has the correct functioning dimension only when mounted. when slipping the seal over the piston rod, it may appear too big.

- the ratio between nominal width and sealing height cs/H should not drop below a value of 1/1.25 (essentially according to ISO 5597 housings for piston and rod seals).

- recovery volume is limited.

function

RS02-A profiles are lip seals designed to seal pressurized space against the atmosphere; mainly for reciprocating movements. the design is based on application in standard hydraulic systems with conventional hydraulic oils. the operating parameters are as defined in the sealing data sheet and material data. requirements deviating from these parameters can be met to a certain degree by changing the geometry in the software program.

for detailed information regarding chemical resistance please refer to our „list of resistance“. for increased chemical and thermal resistance rubber

materials are to be preferred, attention should be paid to restrictions for pressure range and wear resistance. for higher gliding speeds another system should be used (e.g. PTFE materials).

note on special materials:

as the temperature limits are determined by POM, using special materials for the back up ring can expand the temperature limits.

gap dimension

| operating pressure | cs = (ØD – Ød)/2 mm | |||||

| 4 | 5 | 7.5 | 10 | 12.5 | 15 | |

| safe extrusion gap (mm) | ||||||

| 100 bar (10 MPa) | 0.80 | 1.00 | 1.50 | 1.50 | 1.50 | 1.50 |

| 200 bar (20 MPa) | 0.60 | 0.70 | 1.00 | 1.10 | 1.25 | 1.50 |

| 300 bar (30 MPa) | 0.40 | 0.50 | 0.75 | 0.75 | 0.80 | 1.00 |

| 400 bar (40 MPa) | 0.30 | 0.30 | 0.50 | 0.50 | 0.60 | 0.75 |

| 600 bar (60 MPa) | 0.20 | 0.25 | 0.30 | 0.30 | 0.30 | 0.30 |

| 700 bar (70 MPa) | 0.10 | 0.12 | 0.13 | 0.14 | 0.15 | 0.16 |

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,1-0,5 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| Ød | f8 |

| ØD | H10 |

mode of installation

| Ød | type of installation |

| ≤ 6•cs | open mounting space required |

| > 6•cs …..≤ 10•cs | snap mounting with tool |

| > 10•cs | snap mounting by hand |

for inside diameters of 25 mm or more, and dependant on radial cross section (cs), the seals may be snapped into the housing.

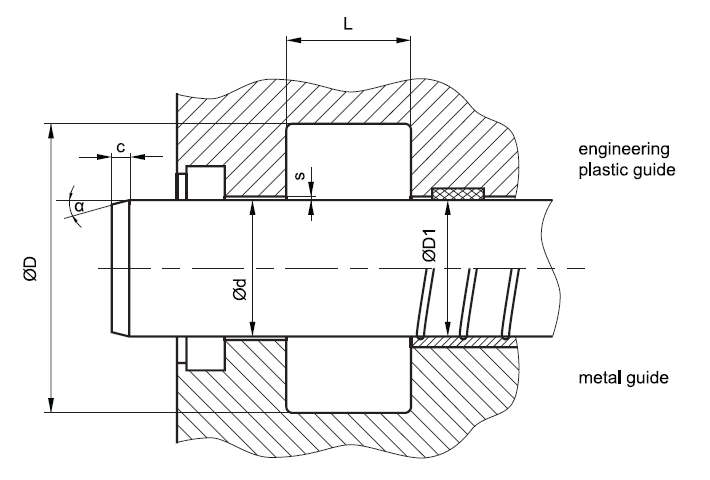

recommended mounting space:

recommended guide tolerance D1:

| d f8 [mm] |

p ≤ 100 [bar] |

100 < p ≤ 200 [bar] |

p > 200 [bar] |

| ≤ 100 | H10 | H8 | H8 |

| > 100 ≤ 200 | H10 | H8 | H7 |

| >200 | H9 | H8 | H7 |

insertion chamfer:

in order to avoid damage to the rod seal during installation, the piston rod is to be chamfered and rounded as shown in the “recommended mounting space” drawing. the size of chamfer depends on the seal type and profile width.

| cs (mm) | c (mm) | |

| α = 15⁰ … 20⁰ | α = 20⁰ … 30⁰ | |

| (2) | 2 | 1 |

| (3) | 3 | 1.5 |

| 4 | 3.5 | 2 |

| 5 | 4 | 2.5 |

| 6 | 4.5 | 3 |

| 7.5 | 5 | 4 |

| 10 | 6 | 5 |

| 12.5 | 8.5 | 6.5 |

| 15 | 10 | 7.5 |

| 20 | 13 | 10 |

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

the ratio between nominal width and seal height cs/H should not drop below 1/1,25. therefore we recommend the following housing heights.

| Ød [mm] | ØD [mm] | L [mm] | cs = (ØD – Ød)/2 [mm] |

| 5 ~ 24,9 | ød + 8 | 6.3 | 4 |

| 25 ~ 49,9 | ød + 10 | 8 | 5 |

| 50 ~ 149,9 | ød + 15 | 10 | 7.5 |

| 150 ~ 299,9 | ød + 20 | 14 | 10 |

| 300 ~ 499,9 | ød + 25 | 17 | 12.5 |

| 500 ~ 699,9 | ød + 30 | 25 | 15 |

| 700 ~ 1000 | ød + 40 | 32 | 20 |

| > 1000 | ød + 40 | 32 | 20 |

fitted:

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.