description

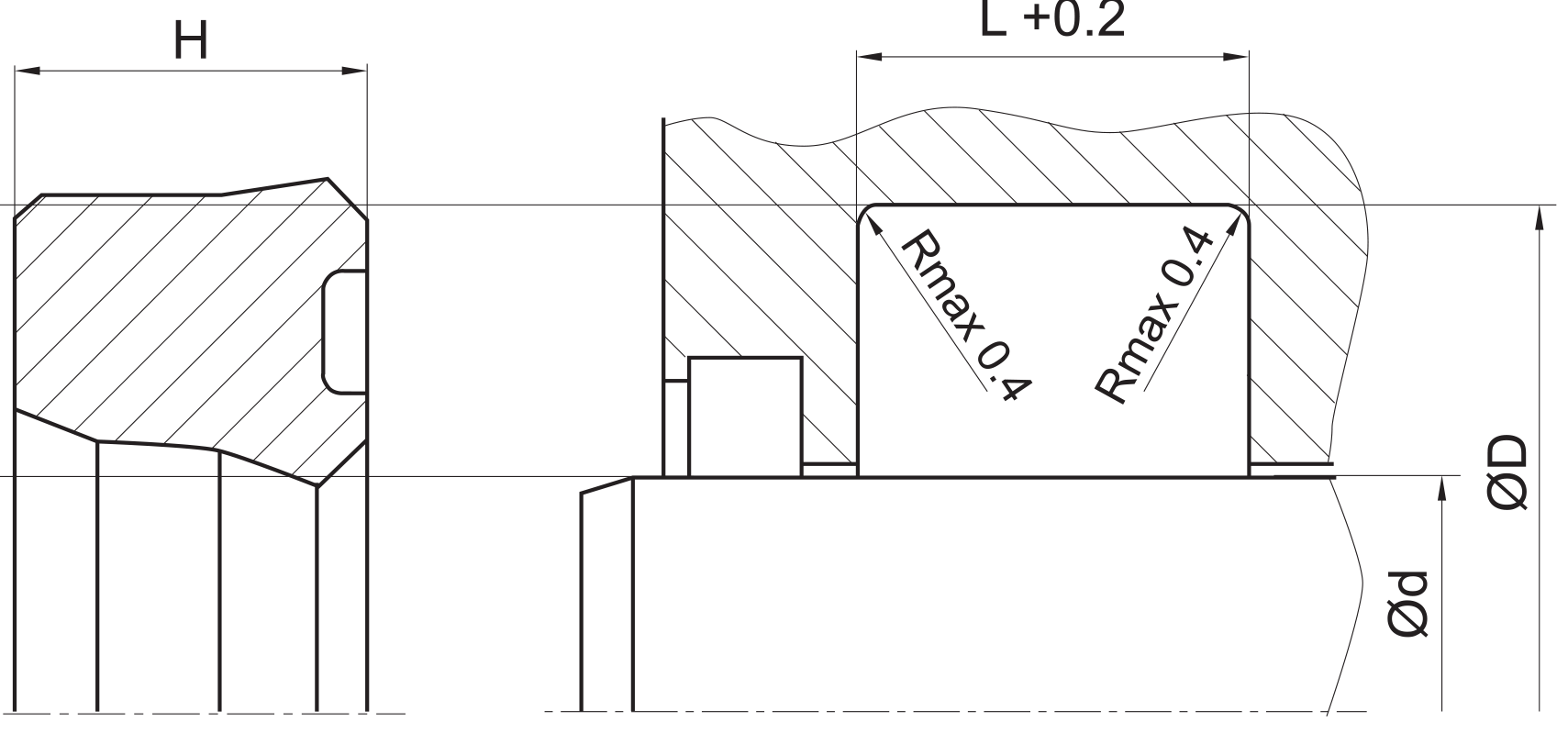

asymmetric compact rod seal with stable fit in the housing. compact design mainly used to seal high viscosity fluids or for extreme small housings, not suitable for high speed applications. RS08 with small groove.

- asymmetric single-acting rod compact seals. the preload is achieved by the inter- nal stress of the seal material.

- interference fit on the outside diameter.

- various materials are available for different purposes.

- snaps into simple grooves (see notes on installation).

- best sealing effect across a wide temperature range.

- sealing effect enhanced by high recovery rate.

- for pressures up to 400 bar as a seal between pressurised space and atmosphere.

- good sealing in all pressure ranges.

- excellent static and dynamic sealing.

- suitable for short travel.

- no reverse leakage (i.e. minor relative motion of the sealing edges when thedirection is changed).

- recommended when holding or positioning under pressure.

- special design for small cross-sections.

- design RS08 with variable groove for reduced preload in special cases (e.g. toohigh friction).

- due to high contact pressure particulary suitable for high viscosity media.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined only.

single acting

the RS08 seal is designed for use as a rod seal.

area of application: hydraulics

- reciprocating rods on hydraulic cylinders,push rods, fittings.

- as rod seals for switching functions (e.g. clutch operation).

- as rod seals for applications with clamping functions or damping elements with high viscosity fluids.

note

- this seal has the correct functioning dimension only when mounted. when slipping the seal over the piston rod, it may appear too large.

- the ratio between nominal width and sealing height cs/H should not drop below a value of 1/1.25 (essentially according to ISO 5597 housings for piston and rod seals).

- high degree of friction.

- high break-awaymoment.

- the recovery volume is smaller than with simple lip seals.

- cross-section limited to 15 mm.

function

RS08 profiles are compact seals designed to seal pressurised space against the atmosphere mainly for reciprocating move- ments. the design is based on application in standard hydraulic systems with conventional hydraulic oils. the operating parameters are as defined in the sealing data sheet and material data. requirements deviating from these parameters can be met to a certain degree by changing the geometry in the software program.

gap dimension

| operating pressure | cs = (ØD – Ød)/2 mm | |||||

| 4 | 5 | 7.5 | 10 | 12.5 | 15 | |

| safe extrusion gap (mm) | ||||||

| 10 | 0.20 | 0.20 | 0.30 | 0.40 | 0.45 | 0.50 |

| 20 | 0.10 | 0.15 | 0.25 | 0.35 | 0.40 | 0.45 |

| 30 | 0.07 | 0.12 | 0.22 | 0.30 | 0.35 | 0.43 |

| 40 | 0.05 | 0.10 | 0.18 | 0.25 | 0.32 | 0.40 |

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤0,1-0,5 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| Ød | f8 |

| ØD | H10 |

mode of installation

for inside diameters of 25 mm or more, and dependant on the radial cross section (cs), the seal can be snapped into the housing.

| Ød | type of installation |

| ≤ 6•cs | open mounting space required |

| > 6•cs …..≤ 10•cs | snap mounting with tool |

| > 10•cs | snap mounting by hand |

recommended mounting space:

recommended guide tolerance D1:

| d f8 [mm] | p ≤ 100 [bar] | 100 < p ≤ 200 [bar] | p > 200 [bar] |

| ≤ 100 | H10 | H8 | H8 |

| > 100 ≤ 200 | H10 | H8 | H7 |

| >200 | H9 | H8 | H7 |

insertion chamfer:

in order to avoid damage to the rod seal during installation, the piston rod is to be chamfered and rounded as shown in the “recommended mounting space” drawing. the size of chamfer depends on the seal type and profile width.

| cs (mm) | c (mm) | |

| α = 15⁰ … 20⁰ | α = 20⁰ … 30⁰ | |

| 4 | 3.5 | 2 |

| 5 | 4 | 2.5 |

| 6 | 4.5 | 3 |

| 7.5 | 5 | 4 |

| 10 | 6 | 5 |

| 12.5 | 8.5 | 6.5 |

| 15 | 10 | 7.5 |

| 20 | 13 | 10 |

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see jet seal pars catalog…

the ratio between nominal width and seal height cs/H should not drop below 1/1,25. therefore we recommend the following housing heights.

| Ød [mm] | ØD [mm] | L [mm] | cs = (ØD – Ød)/2 [mm] |

| 5 ~ 24,9 | Ød + 8 | 6.3 | 4 |

| 25 ~ 49,9 | Ød + 10 | 8 | 5 |

| 50 ~ 149,9 | Ød + 15 | 10 | 7.5 |

| 150 ~ 299,9 | Ød + 20 | 14 | 10 |

| 300 ~ 499,9 | Ød + 25 | 17 | 12.5 |

| 500 ~ 699,9 | Ød + 30 | 25 | 15 |

| 700 ~ 1000 | Ød + 40 | 32 | 20 |

| > 1000 | Ød + 40 | 32 | 20 |

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.