description

rod seal S09-SD consisting of profile ring and O-ring as a preload component

application

category of profile

machined or molded/standard/trade product.

double acting

the RS 09-FI seal is designed for use as a piston seal.

area of application: hydraulics advantages

rod seal for lower pressure range with properties of :

- low friction

- low housing height

operating parameters & material

| material | temperature°C | max-surface speed | max-pressure | |

| sealing element | energizer | |||

| PTFE +40%bronze | NBR 70 SH-A | -30 °C … +100 | 2 m/s | 160 bar (16 MPa) |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

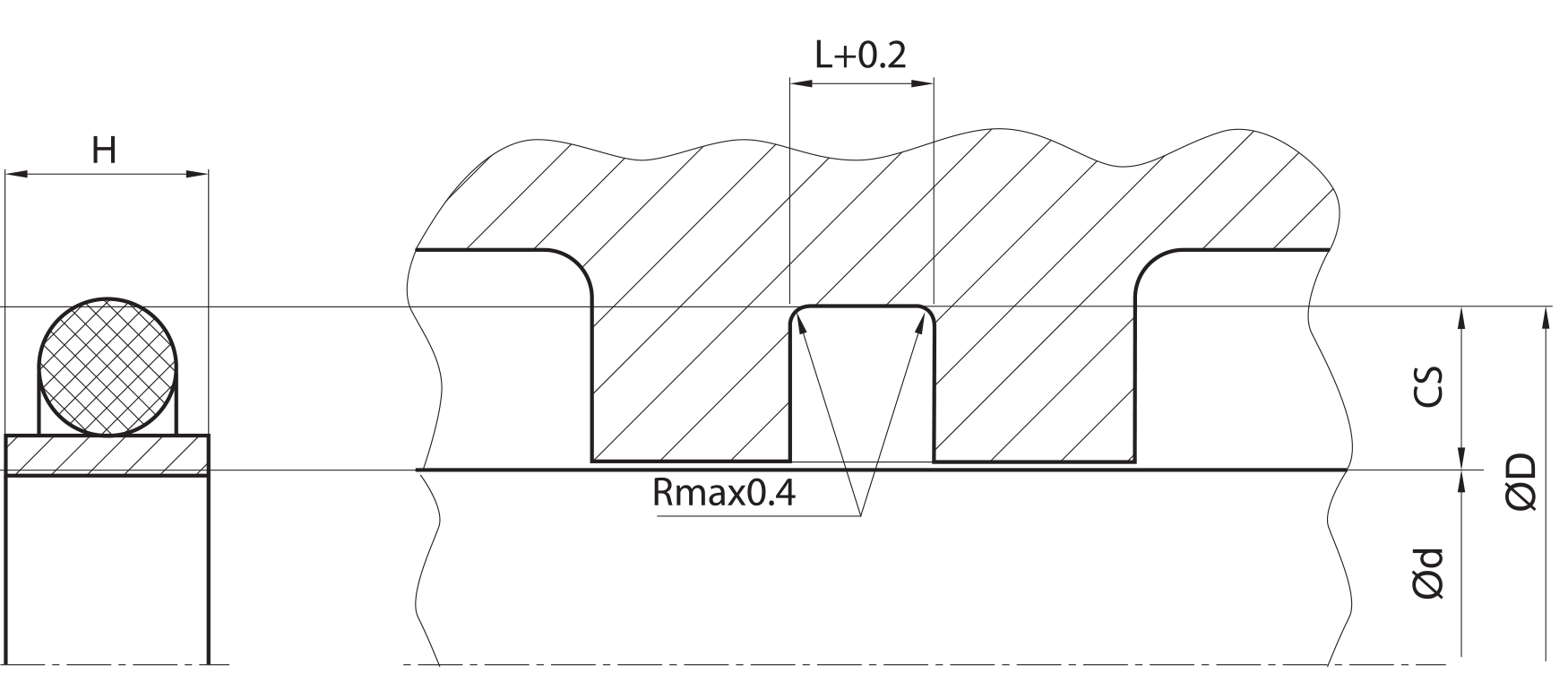

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2 | ≤0,05-0,3 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| Ød | f8 |

| ØD | H10 |

gap dimension

the decisive factor for the function of the seal is the largest gap dimension occurring during operation on the non-pressurised side of the seal.

we recommend a metal guide H8/f7.

fitting & installation

careful fitting is a prerequisite for the correct function of the seal.

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see JET SEAL PARS catalog…

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.