description

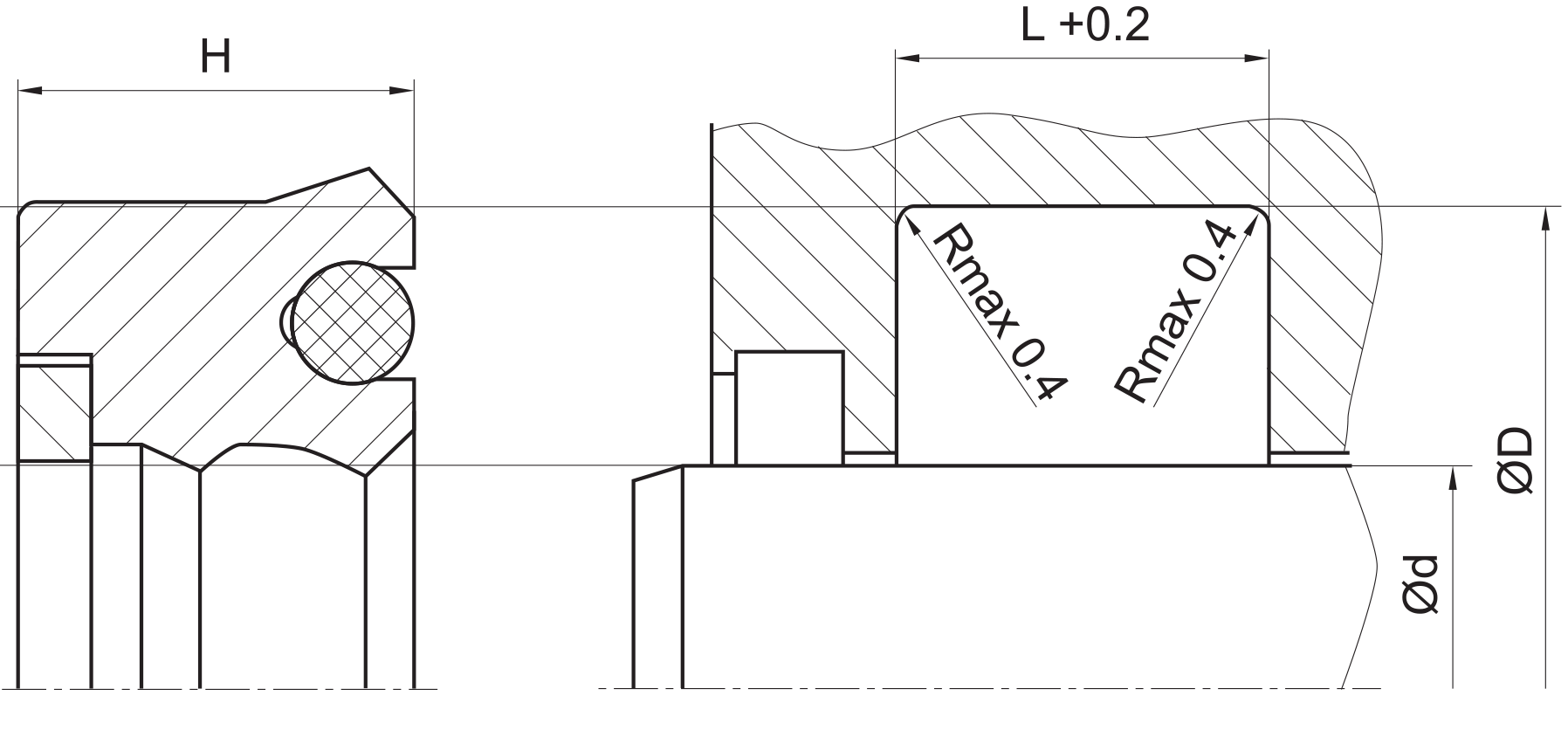

the profile RS17-C rod seal is the result of a further development od us with a sec- ondary sealing lip and a highly extrusion resistant back-up ring. due to the secondary lip, additional lubricant is retained in the sealing gap. (this greatly prevents dry-run and wear, thus increasing the seal’s service life).

additionally, this second sealing lip may even act as a substitute for a costly tandem arrangement when, under certain conditions, satisfactory sealing performance can only be achieved by two seals placed one behind the other in separate installation grooves. these seals may be used for all applications where the physical properties of normal or fabric reinforced elastomers are insufficient.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

single acting

the RS17-C SA seal is designed for use as a rod seal.

area of application: hydraulics

mainly for the sealing of piston rods and plungers on heavy duty applications in mobile and stationary hydraulics.

advantages

- unusually high wear resistance.

- insensibility against shock loads and pressure peaks.

- high resistance against extrusion.

- low compression set.

- suitable for hardest working conditions.

- sufficient lubrication due to pressure medium between the sealing lips.

- increased sealing performance at zero pressure.

- air penetration from out-side is largely prevented.

- easy installation.

operating parameters & material

| sealing element | energizer | back-up ring | temperature | max. surface speed | max. pressure 1 |

| PU (93 Shore A) | NBR (70 shore A) | POM / PA 2 | -35˚C … + 110˚C | 0,5 m/s | 500 bar (50 MPa) |

the stated operation conditions represent general indications. it is recommended not to use all maximum values simultaneously. surface speed limits apply only to the presence of adequate lubrication film.

1 pressure ratings are dependent on the size of the extrusion gap.

2 POM up to ø260 mm, PA above ø260 mm.

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | ≤2,5 | ≤ 0.6 |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤ 4.0 |

tolerance recommendation

| seal housing | tolerances |

| Ød | f7 |

| ØD | H11 |

fitting & installation

the seals should have an axial clearance (see columns H and L). to avoid damage at the sealing lips, the seals should not be pulled over sharp edges during installation.

normally these seals may be snapped into closed grooves. where access is restricted special assembly tools may be required. proposals for the design of such tools will be provided on request. tolerance guidelines H8/f7.

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see Jet seal pars catalog…

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.