description

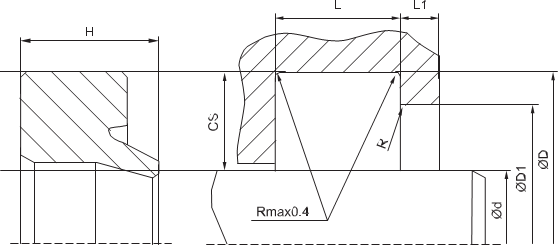

as profile WR 02, but without back support area special housing design according ISO

6195-Type C.

- the seal profile and close machining tolerances provide a good static seal for the outside diameter, assisting in the prevention of ingress of humidity and foreign matter via the outside diameter.

- the design of the wiping lip aids the recovery of residual oil film while exclusion of foreign matter is maintained.

- the provision of a support shoulder, along with relief grooves on the mating seal face, prevents tilting of the wiper and pressure build up on the trailing side.

- support shoulder not included in design WR 02-B .

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

single acting

area of application: hydraulics

- reciprocating rods on hydraulic cylinders.

- push rods and valve stems.

- (materials must be selected according to operating requirements).

- the WR 02-B design is to be used for mounting spaces according to ISO 6195-1986 type C.

function:

WR 02-B wipers are designed to keep dust, dirt, sand and metal chips away from the sealing and guiding elements, thereby avoid- ing abrasive damage caused by external contamination.

for detailed information regarding chemical resistance please refer to our “list of resistance”. for increased chemical and thermal resistance rubber materials are to be preferred, polyurethan materials increase wear resistance.

application

not bolded symbols; please consult our technical for application limitations

category of profile

machined or molded/standard/trade product.

single acting

area of application: hydraulics

- reciprocating rods on hydraulic cylinders.

- push rods and valve stems.

- (materials must be selected according to operating requirements).

- the WR 02-B design is to be used for mounting spaces according to ISO 6195-1986 type C.

function:

WR 02-B wipers are designed to keep dust, dirt, sand and metal chips away from the sealing and guiding elements, thereby avoid- ing abrasive damage caused by external contamination.

for detailed information regarding chemical resistance please refer to our “list of resistance”. for increased chemical and thermal resistance rubber materials are to be preferred, polyurethan materials increase wear resistance.

surface quality

| surface roughness |

Rtmax (μm) |

Ra (μm) |

| sliding surface | according to seal data | |

| bottom of groove | ≤6,3 | ≤1,6 |

| groove face | ≤15 | ≤3 |

tolerance recommendation

| seal housing | tolerances |

| L < 10 mm | 0.2 |

| L ≥ 10 mm | 0.3 |

| D1 | H11 |

| D | H11 |

| cs | R [mm] |

| ≤ 5 | max. 0,3 |

| >5…….≤ 7,5 | max. 0,4 |

| >7,5….≤ 10 | max. 0,6 |

| > 10 | max. 0,8 |

mode of installation

the prerequisites for perfect functioning are careful fitting and an accurately dimensioned mounting space. in general, wipers snap easily into their housings when distorted into a kidney shape (over 20mm diameter).

seal & housing recommendations

please note that we are able to produce those profiles to your specific need or any non standard housing. for detail measurements, please see jet seal pars catalog…

don’t hesitate to contact our technical department for further information or for special requirements (temperature, speed etc.), so that suitable materi- als and/or designs can be recommended.